Integrated Automation for your Machines

One Controller, One Network, One Software: The Power of One

Make It Integrated

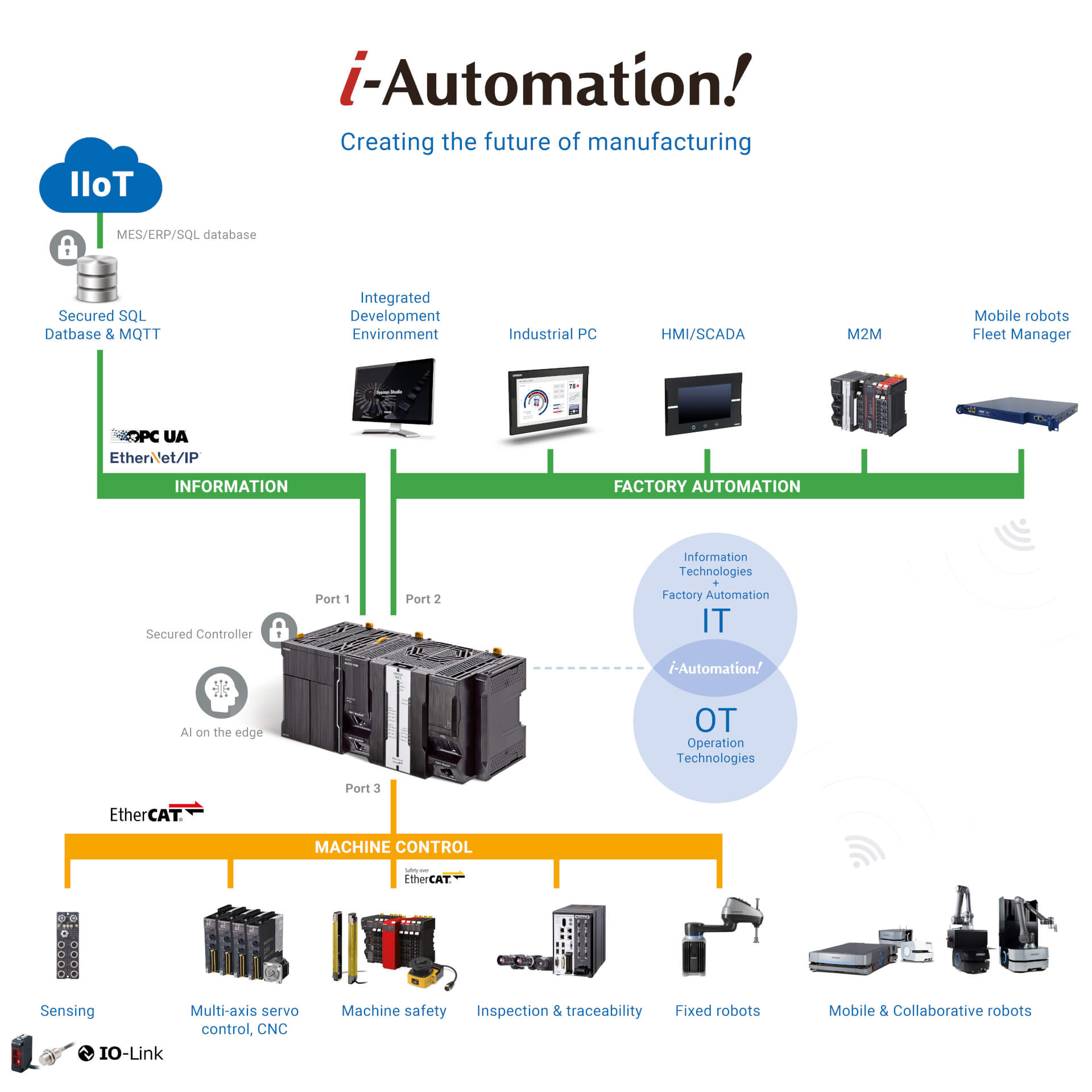

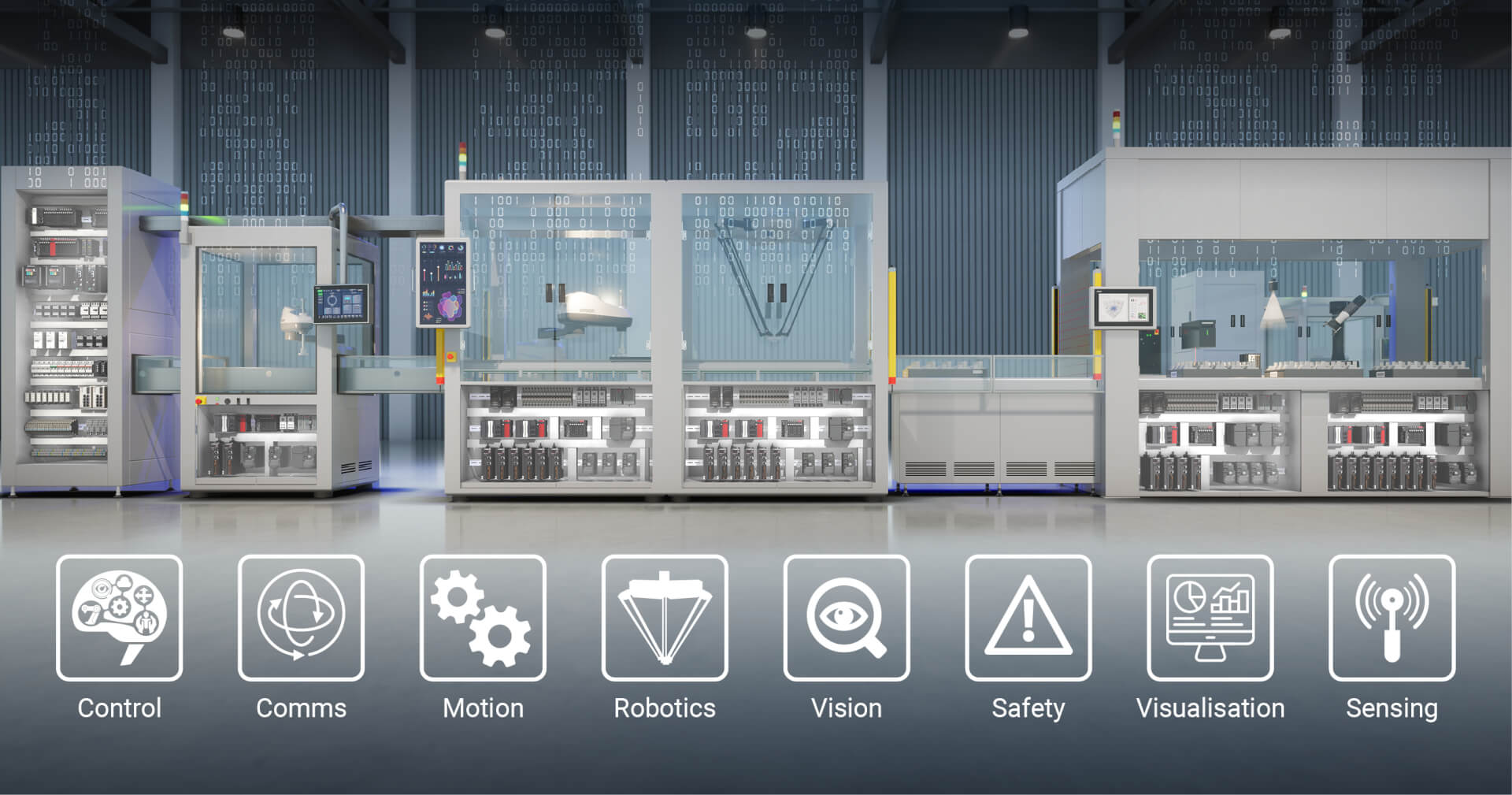

Introducing the Sysmac Platform – OMRON’s Integrated Automation, designed to help you build smarter, more competitive machines.

One controller that orchestrates your entire machine – from control, motion, safety, vision, sensing, robotics, and visualization to communications.

One software, built on open standards, that gives you the freedom to create smarter, more connected machines. And the best part? It’s incredibly easy to use.

One network that brings together safety, diagnostics, and control, ensuring efficient performance and reliable integration.

Total control. Fully integrated. Ready to innovate.

What is OMRON’s Sysmac Platform?

Sysmac is OMRON’s fully integrated automation platform that combines modular hardware, a real-time EtherCAT-based architecture, and software to unify every machine function into one connected ecosystem.

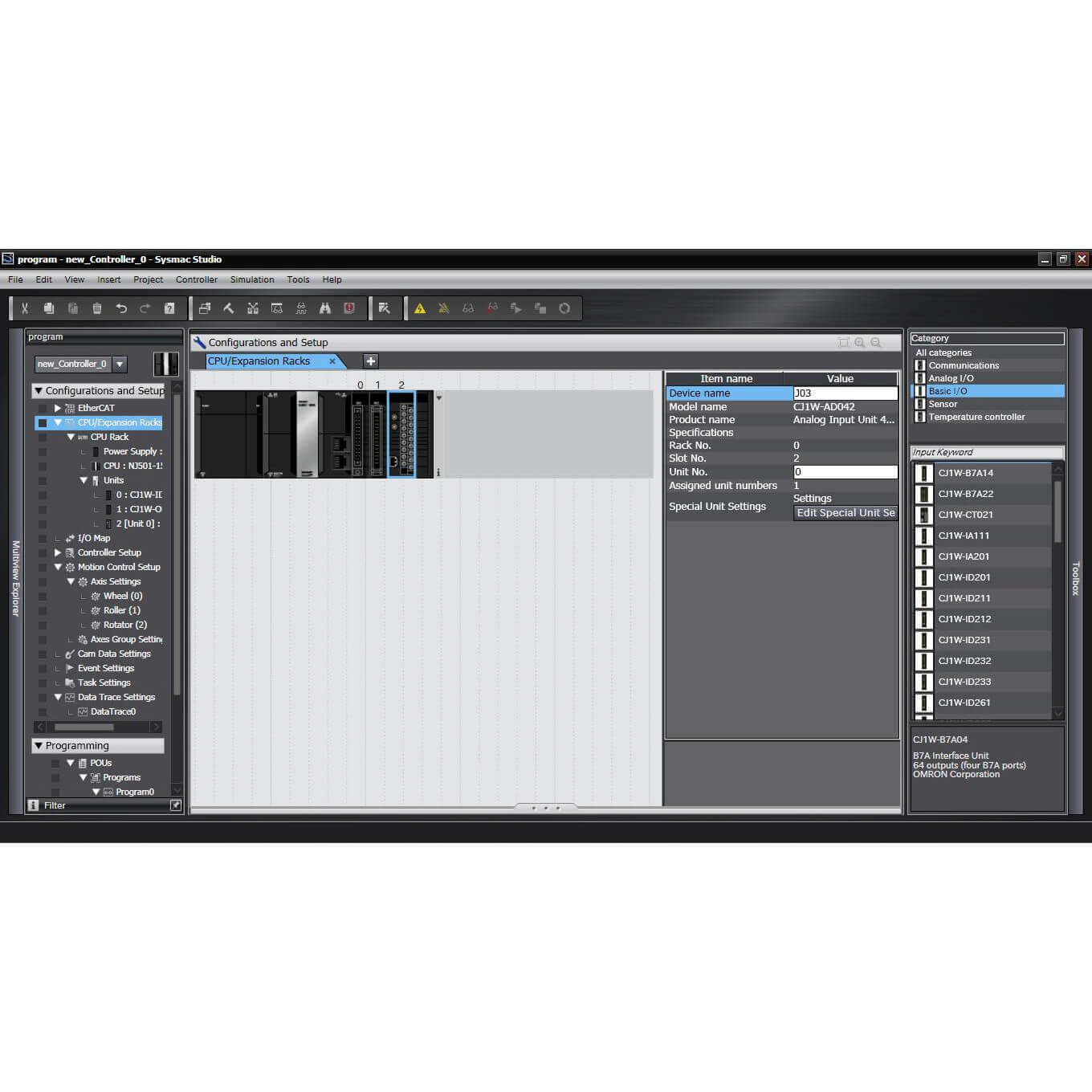

At the heart of Sysmac is Sysmac Studio, an integrated development environment (IDE) designed to simplify programming, visualisation, and commissioning across the full machine lifecycle. Sysmac Studio lets you configure and control your machine from one easy-to-learn intuitive interface. Visualize changes and confirm feasibility using 3D simulation

-

OMRON's Sysmac industrial automation platform for integrated machine control and factory automation

OMRON's Sysmac Platform offers synchronous and seamless control of all machine devices and advanced functionality such as motion, robotics and database connectivity. This multidisciplinary concept allows you to simplify solution architecture, reduce programming and optimize productivity. OMRON's Sysmac Platform makes efficient, flexible and cost-effective manufacturing possible. The Sysmac technology platform ensures a flexible and integrated production business model. It features: 👉 One control for the entire machine or process 👉 Open communication and programming standards 👉 Joins EtherNet/IP for factory automation network with the best Ethernet-based machine control network, EtherCAT 👉 True Integrated Development Environment (IDE) to simplify all of the disciplines of automation in one place-motion, sequencing, safety, networking, vision inspection, and IIoT 👉 Synchronous control for machine performance and time series data collection for IIoT applications 👉 Designed for the future factories in mind by incorporating AI, machine learning, industry 4.0, traceability and predictive maintenance technologies 00:00 Introduction 00:35 One Integrated Controller 02:15 Integrated Safety 02:30 Integrated HMI 02:46 Integrated Robotics 02:58 Integrated Motion 03:20 Integrated I/O 04:13 Sysmac Studio 05:24 Sysmac Architecture 06:11 Data Solutions 06:23 AI Controller

07:00

Sysmac Studio 3D Simulation IDE

The Sysmac Studio 3D Simulation IDE is the first industry-integrated environment that unifies automation design, robot and device control, and 3D simulation in one platform. This enables precise virtual testing that mirrors real-world operations.

It reduces equipment delivery times, it supports simultaneous line start-ups and streamlines modifications.

The IDE enhances efficiency with features like IEC 61131-3 compliance, an integrated CAM editor, integrated motion/sequence simulation, and advanced security.

-

OMRON Sysmac Studio Robotics Edition - 3D Visualizer and Collision Detection

In this OMRON Sysmac Studio Robotics Edition how-to video, we'll continue with an in-depth look into 3D Visulizer, and how it can be used to set up simulations for projects. We will also try scripting for Collision Detection. For more information on OMRON Sysmac Studio, please visit:

19:38

Benefits of Sysmac Automation Platform to Automate Machines

Easy to use

Training libraries to speed up & improve quality

Designed for engineers – Built for customised machines

Modern machine builders face a growing challenge: almost every machine becomes a custom project. From layout changes to product handling variations, technical teams must adapt designs, often under tight deadlines and limited resources.

OMRON’s Sysmac Platform was developed to meet this reality head-on.

Download and read our expert article by Industry Manager John van Hooijdonk how to turn machine customization from your biggest challenge into a competitive advantage by adopting modular design principles.

Easy Integration: Built to Fit Your Environment

Seamless integration is a core strength of the Sysmac Platform—saving time, reducing risk, and future-proofing your automation strategy.

-

Open Architecture

EtherCAT & EtherNet/IP for high-speed, vendor-neutral connectivity

Compatible with third-party sensors, robots, and PLCs

Easy scale-up from single machines to full factory floors

-

Plug-and-Play Simplicity

Unified software (Sysmac Studio) reduces toolchain complexity

Pre-built libraries and open programming standards

Minimal need for custom coding or middleware

-

Faster Commissioning

Built-in 3D simulation + Automation Playback for pre-deployment validation

Save engineering time and reduce setup errors

Shorter development cycles, quicker ROI

Sysmac Family

-

Simplified machine design and maintenance

-

Advanced direct reflective photoelectric sensors

-

High-performance color mark sensor

-

High-performance digital fiber amplifier

-

Faster machine operation, cameras for every application

-

The Integrated AC Drivers Solution

-

NA Series -The Sysmac HMI

-

Modular IP20 IOs

-

From single machine to production line all, safety interconnect

-

Information, Control and Safety

-

Four-axis parallel robot achieves high speed and high precision

-

Boost Your Productivity

-

Gain more out of production with a higher payload and faster cycle time