FH Vision System

Faster machine operation, cameras for every application

- High-Resolution Imaging: Capture fine details and subtle defects with exceptional clarity.

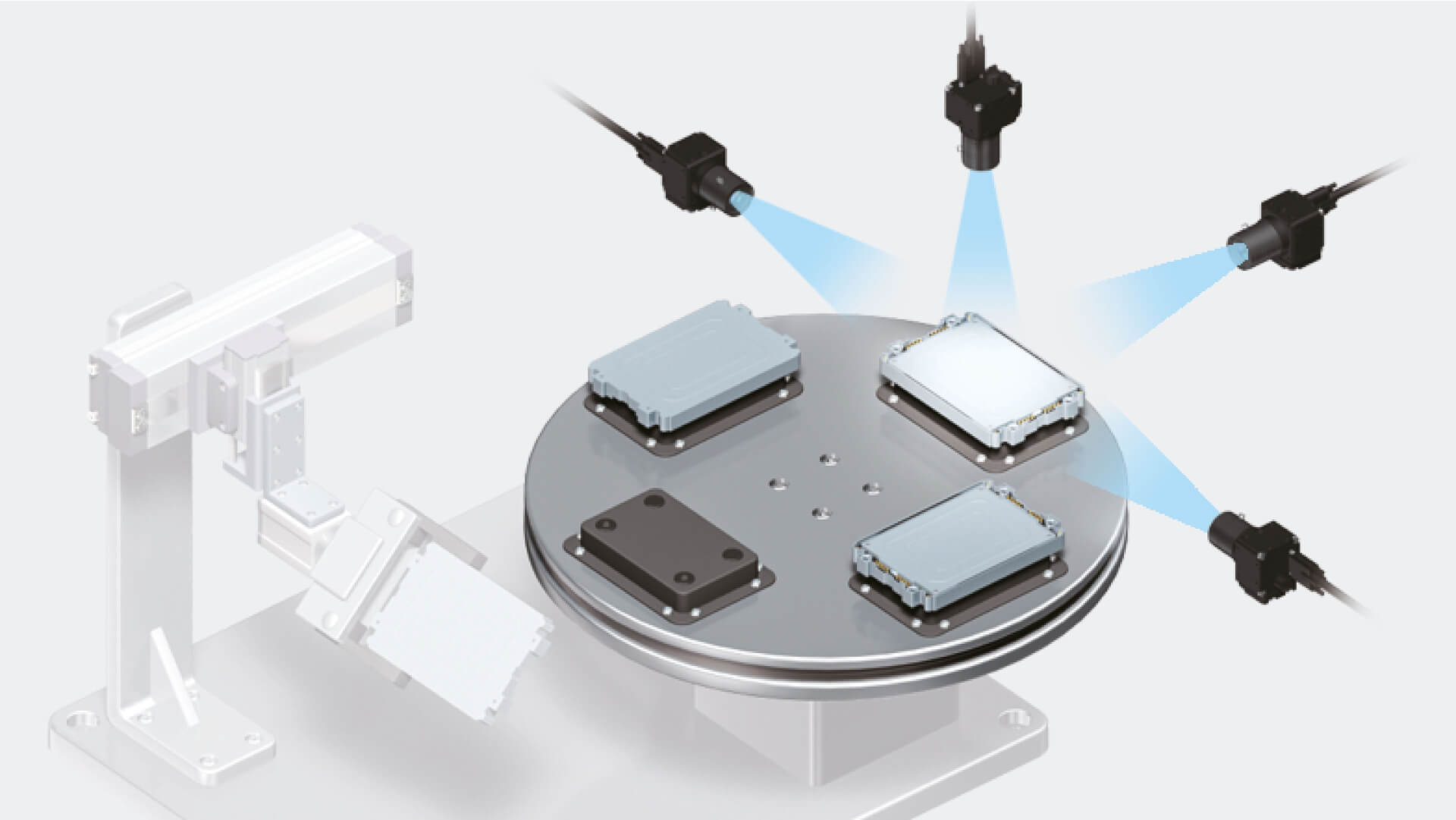

- Multi-Camera Support: Seamlessly integrate multiple cameras for comprehensive inspection coverage.

- Customizable Inspection Tools: Tailor inspection criteria to match your specific requirements with a wide range of built-in tools.

- Remote Monitoring and Control: Monitor production lines and manage inspections remotely for enhanced efficiency and convenience.

- Robust Integration Capabilities: Easily integrate our FH Vision System with existing machinery and automation systems for seamless operation.

- Linescan camera support: Connect up to 4 Omron Sentech GigE Linescan cameras, 2K,4K & 8K options.

Need assistance?

We’re here to help! Reach out, and our specialists will assist you in finding the best solution for your business.

Ota minuun yhteyttä FH Vision System

Kiitos yhteydenotostasi. Otamme teihin yhteyttä mahdollisimman pian.

Meillä on teknisiä ongelmia. Emme ole pystyneet vastaanottamaan lomakettasi. Pahoittelemme ja pyydämme yrittämään uudelleen myöhemmin.

DownloadTarjous FH Vision System

Tällä lomakkeella voit pyytää tarjouksen valitsemastasi tuotteesta. Täytäthän kaikki *-merkityt kentät. Henkilökohtaisia tietojasi käsitellään luottamuksellisesti.

Kiitos tarjouspyynnöstä. Toimitamme tarvittavat tiedot teille mahdollisimman pian.

Meillä on teknisiä ongelmia. Emme ole pystyneet vastaanottamaan lomakettasi. Pahoittelemme ja pyydämme yrittämään uudelleen myöhemmin.

DownloadFeatures

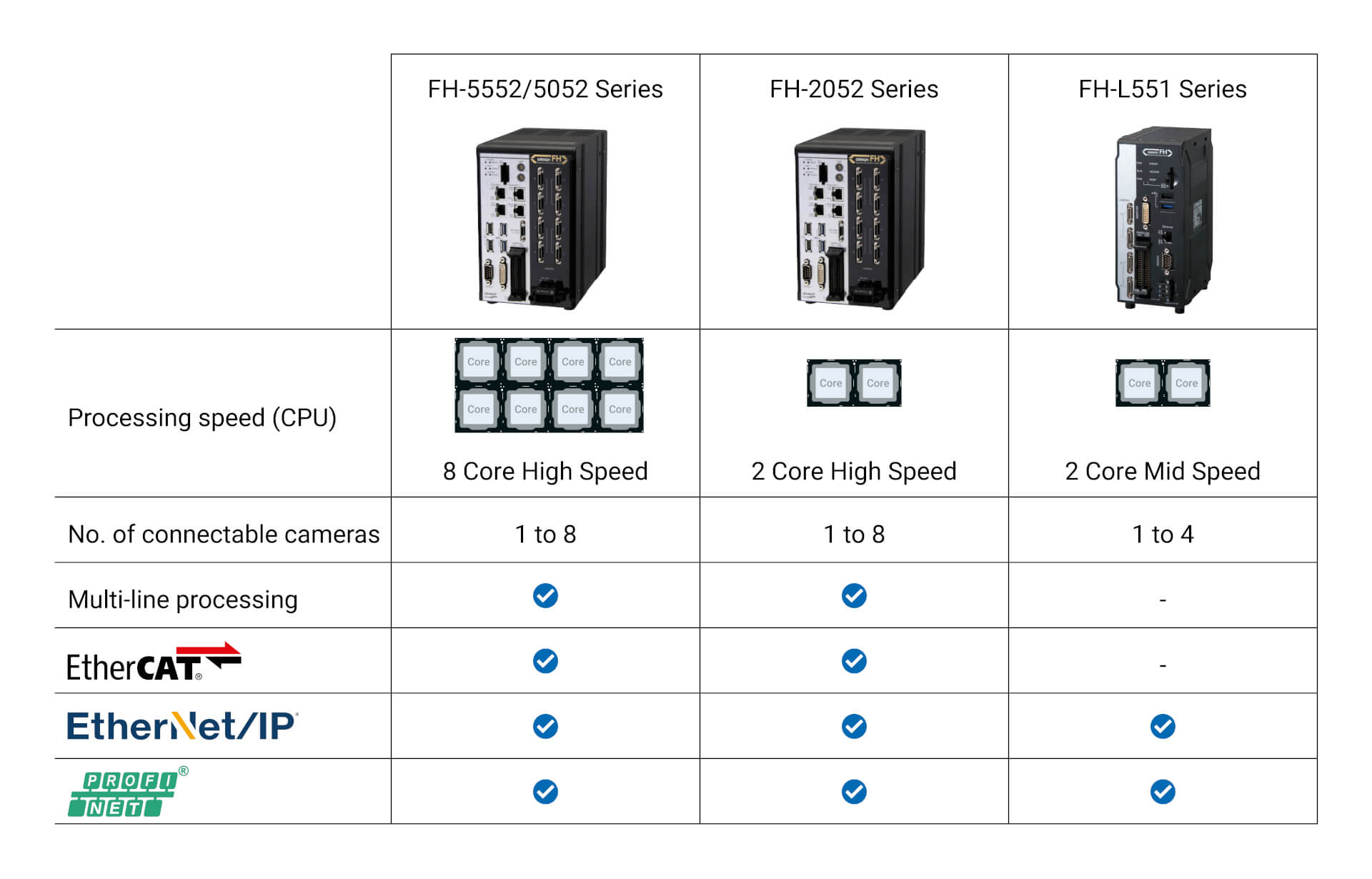

Powerful controllers for fast and precise inspection and measurement

Select the best controller to suit your requirements. All controllers can share the same settings, bringing flexibility to machine design.

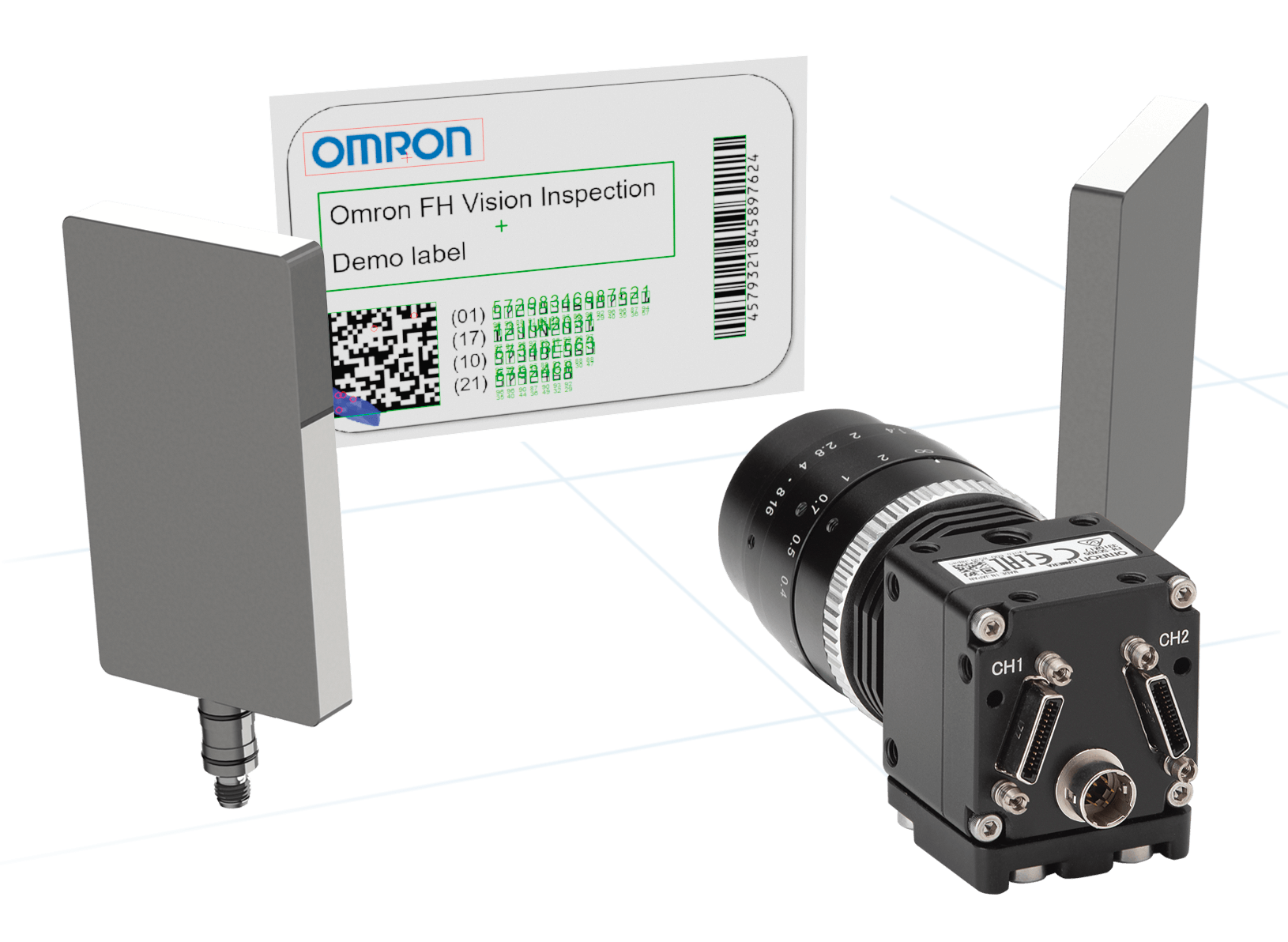

Complete line up of High Speed / High Resolution cameras

FH Cameras are designed for use in all types of object inspection, position/orientation, code reading and measurement applications, this compact camera and controller system is easily integrated into almost any machine or robot. The system is uniquely capable of providing faster, more precise work throughput – to give you more efficiency, less cost, and more.

Extended Sensing with SWIR & Polarized Cameras

Omron has significantly advanced its image sensing capabilities by expanding its camera portfolio. We now offer two SWIR camera resolutions and two polarized resolution cameras. These additions greatly enhance the sensing range and versatility of the FH line up

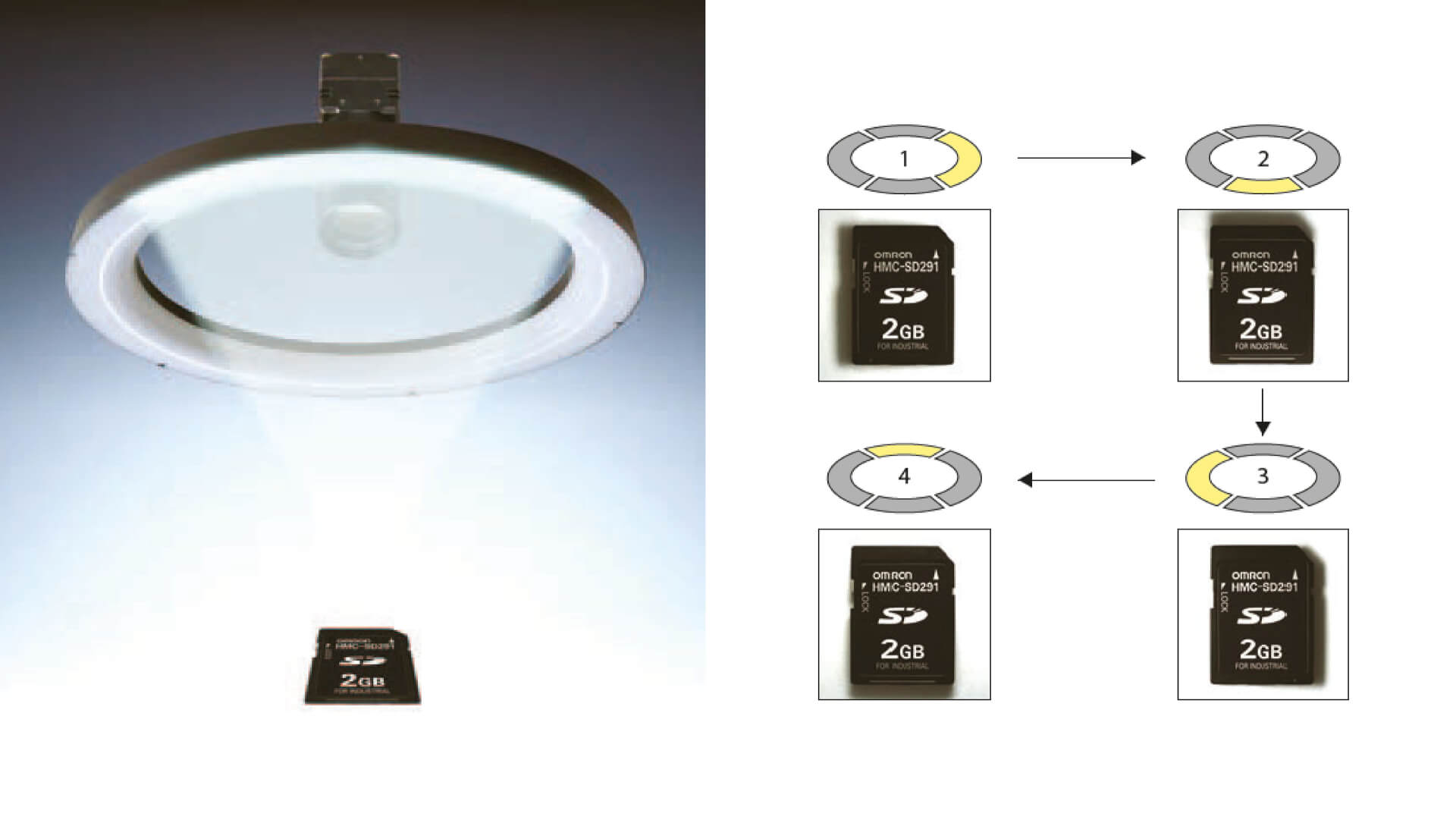

Advanced Photometric Stereo Imaging

The FH Photometric Stereo Light can be used with standard or high-resolution cameras up to 20.4 Mpix. To detect dents and surface damage with high accuracy. Four lights are lit in turn, and variations in brightness are analyzed. Printed characters with little variation in brightness even under different illumination directions are extracted as texture, and a dent with huge variation in brightness is extracted as a shape

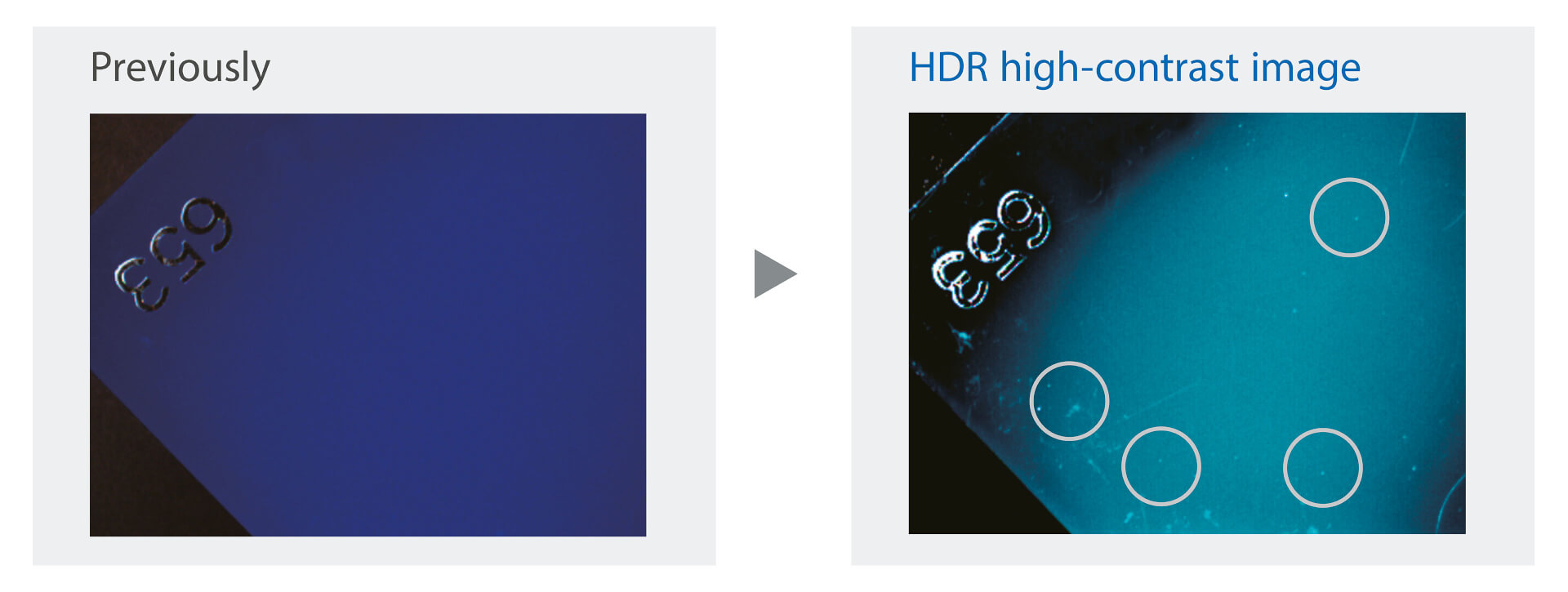

HDR Imaging

HDR helps create optimized images under variable ambient conditions. Once you specify the optimum area to capture on the image, the FH Series automatically adjusts the shutter speed while capturing images and combining them.

Comprehensive Rule-based Vision Tools

Omron’s FH rule-based vision tools lead the way in modern industrial automation, delivering cutting-edge solutions for quality control, inspection, and process optimization. Utilizing advanced algorithms and precise imaging technology, these tools execute complex tasks with exceptional accuracy and reliability. Engineered for user-friendliness, Omron's vision tools ensure seamless integration into existing systems and require minimal setup time.

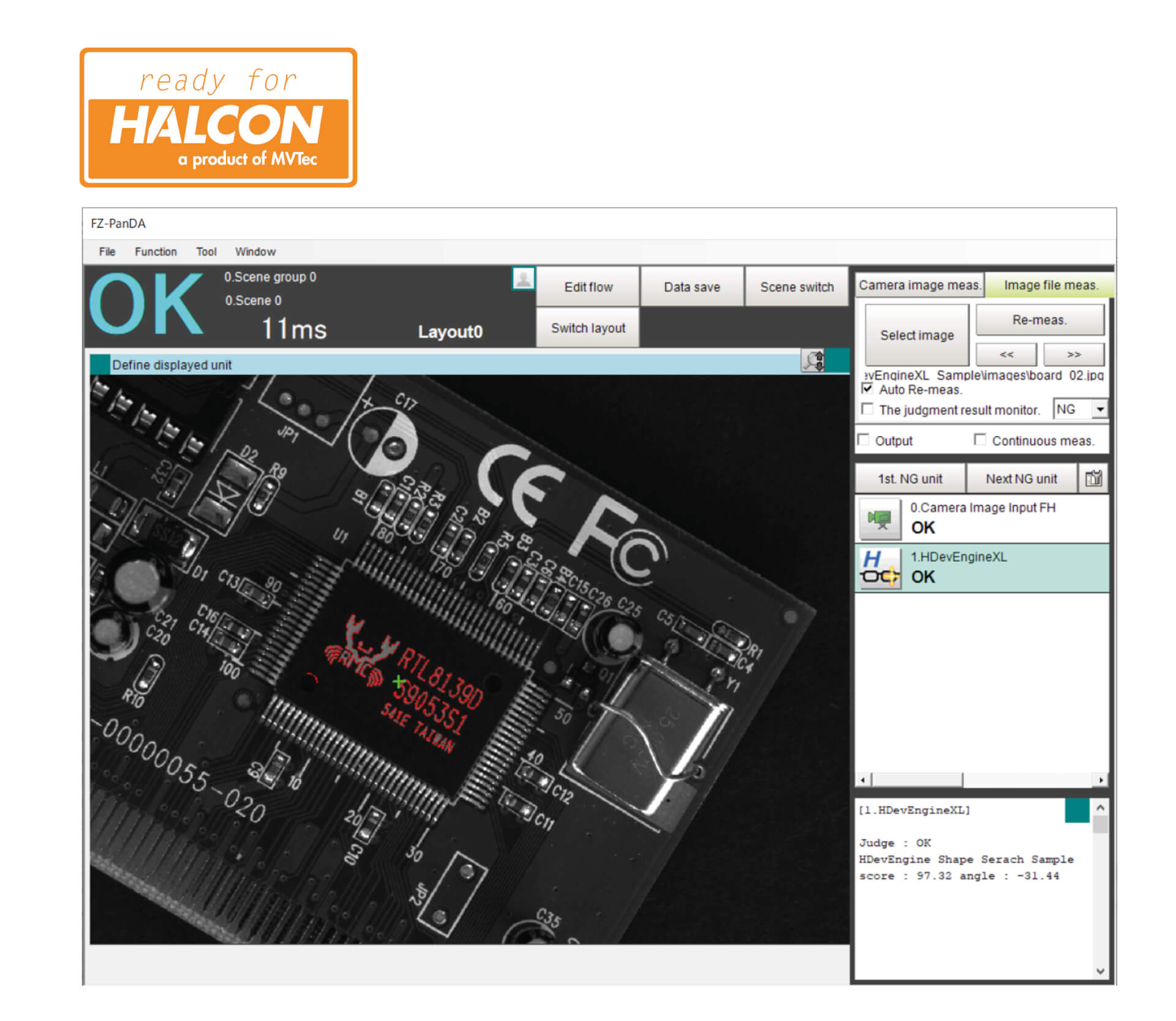

Open FH

In addition to Omron's proprietary Vision algorithms, the FH Vision controller is compatible with Vision algorithms developed using MVTec's Halcon HDevelop software. This flexibility allows manufacturers to select the best algorithmic approach for their specific application requirements, ensuring optimal performance and efficiency in their vision solutions

AI Features

AI & Rule-based processing

Stable and Reliable Hardware:

Omron's vision hardware is designed to withstand demanding industrial environments, delivering consistent performance even in challenging conditions. Its robust build ensures long-term reliability, reducing downtime and maintenance efforts.

Seamless Integration of AI Inspection Tools:

Enhance your traditional rule-based inspection system with AI capabilities. The Omron FH Series allows you to add advanced AI inspection tools to your existing setup, combining the accuracy of rule-based inspection with the adaptability of AI-driven analysis.

Cost-Effective Perpetual License Model:

Say goodbye to the hassle of annual budgeting and contract renewals. The Omron FH Series offers a perpetual license model, giving you long-term access to cutting-edge inspection technology without recurring subscription fees.

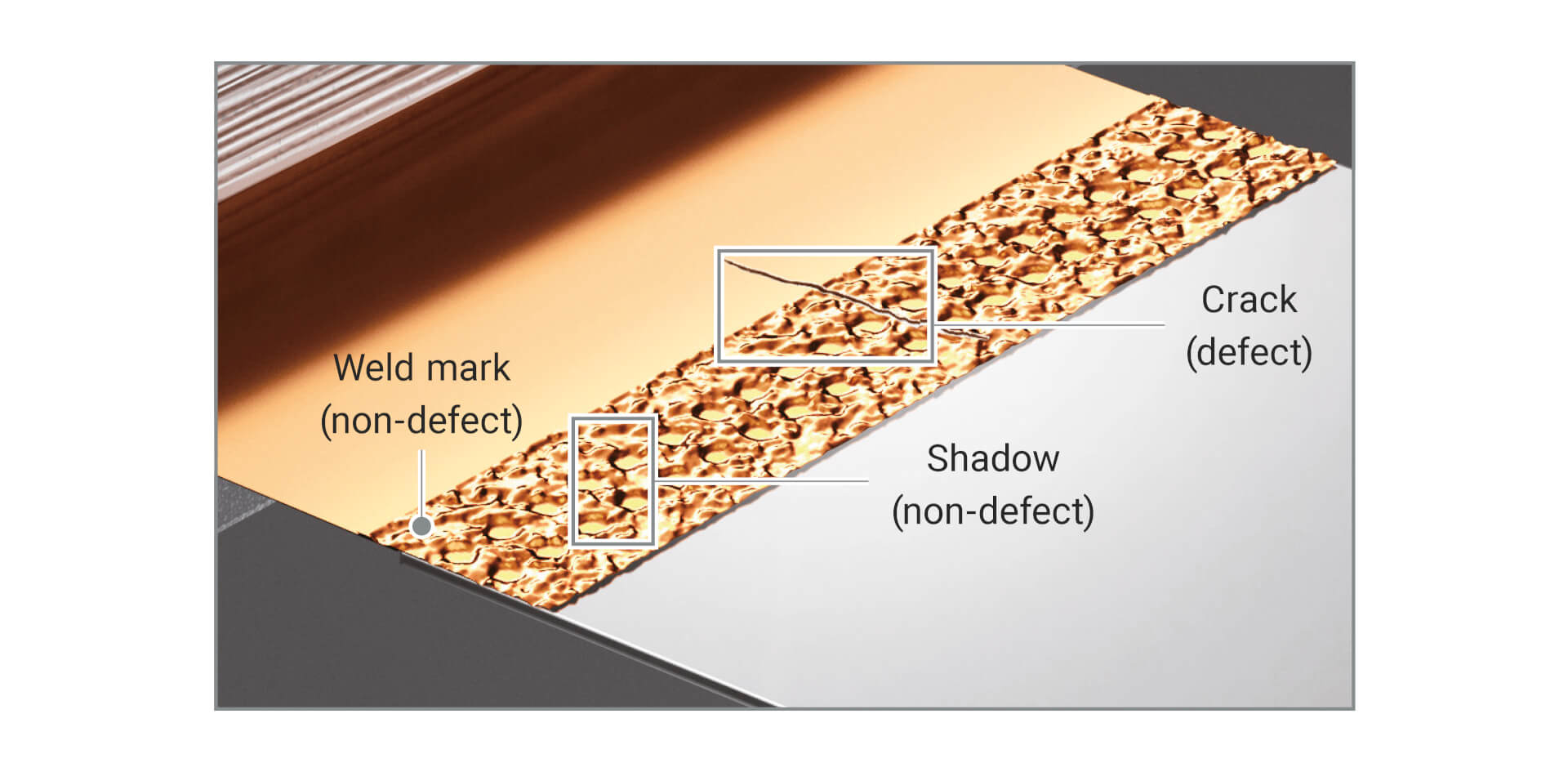

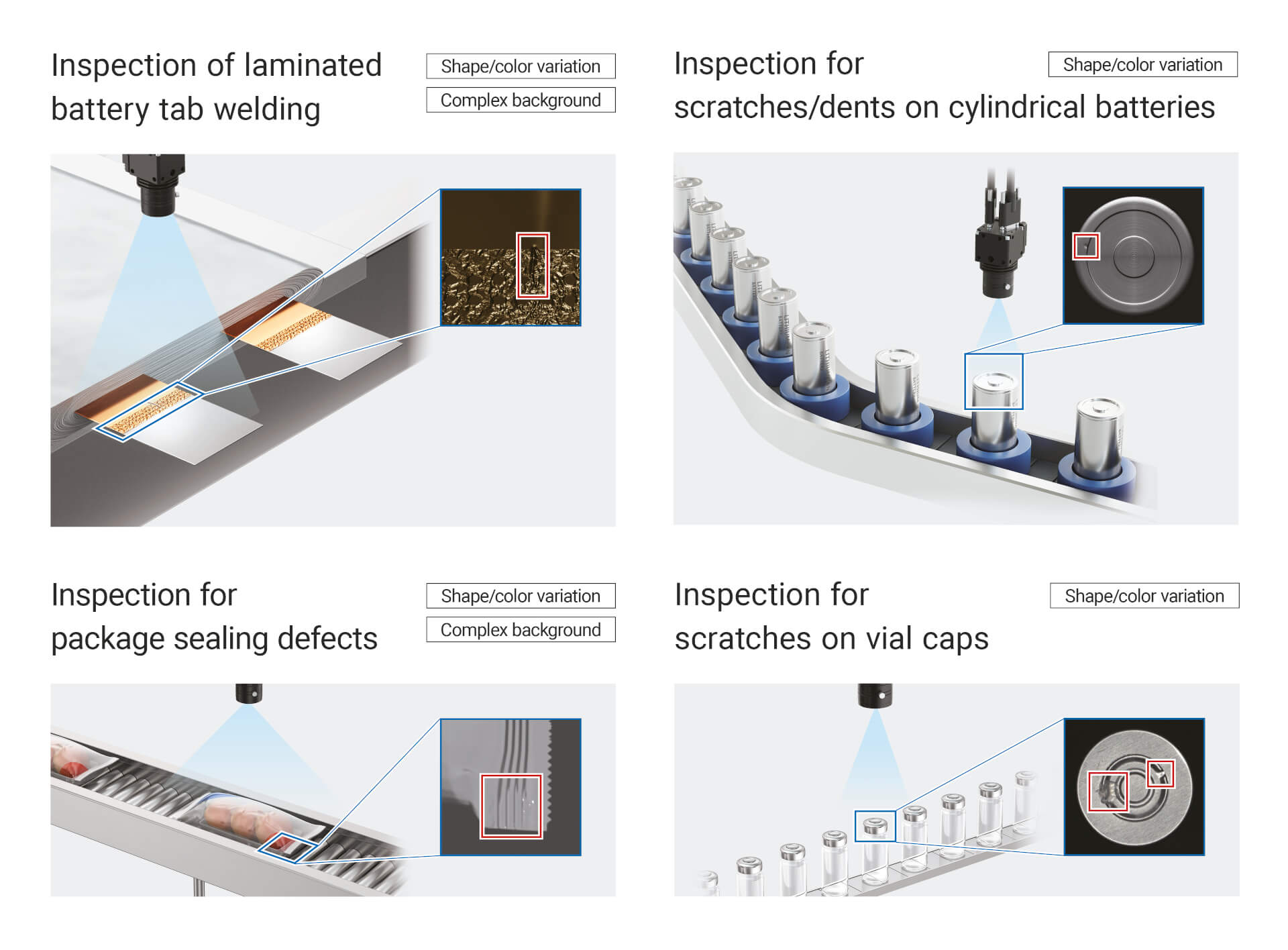

AI Defect Inspection

The Omron AI Defect Inspection algorithm is a game-changer for quality control. It uses advanced artificial intelligence to spot defects accurately while keeping false positives to a minimum. This system is designed to tackle common challenges like shape, colour, and gloss variations, as well as tricky backgrounds, making real-time inspection on the factory floor more precise and efficient. What really sets it apart is its self-learning capabilities and easy three-step setup, making sophisticated defect detection straightforward and dependable. Whether you're in the automotive, electronics, food, or pharmaceutical industry, Omron’s intelligent vision solutions deliver the accuracy and efficiency you need.

3 Step Configuration Process

- Image Preparation: Prepare your images in to “Non-defective” and “defective” products

- Annotation: Mark the defects as if you were pointing to them out to another person.

- Learning: Simply start the self-learning process and configuration will be complete in a matter of minutes.

Eliminate Overdetection

- Advanced AI Algorithm: Reduces false positives from shape, colour, and gloss variations.

- Self-Learning Technology: Quickly trains the model with minimal images, ensuring reliable and reproducible results.

- Context-Aware Processing: Detects only significant defects, ignoring irrelevant background noise

Trusted in Diverse Industries

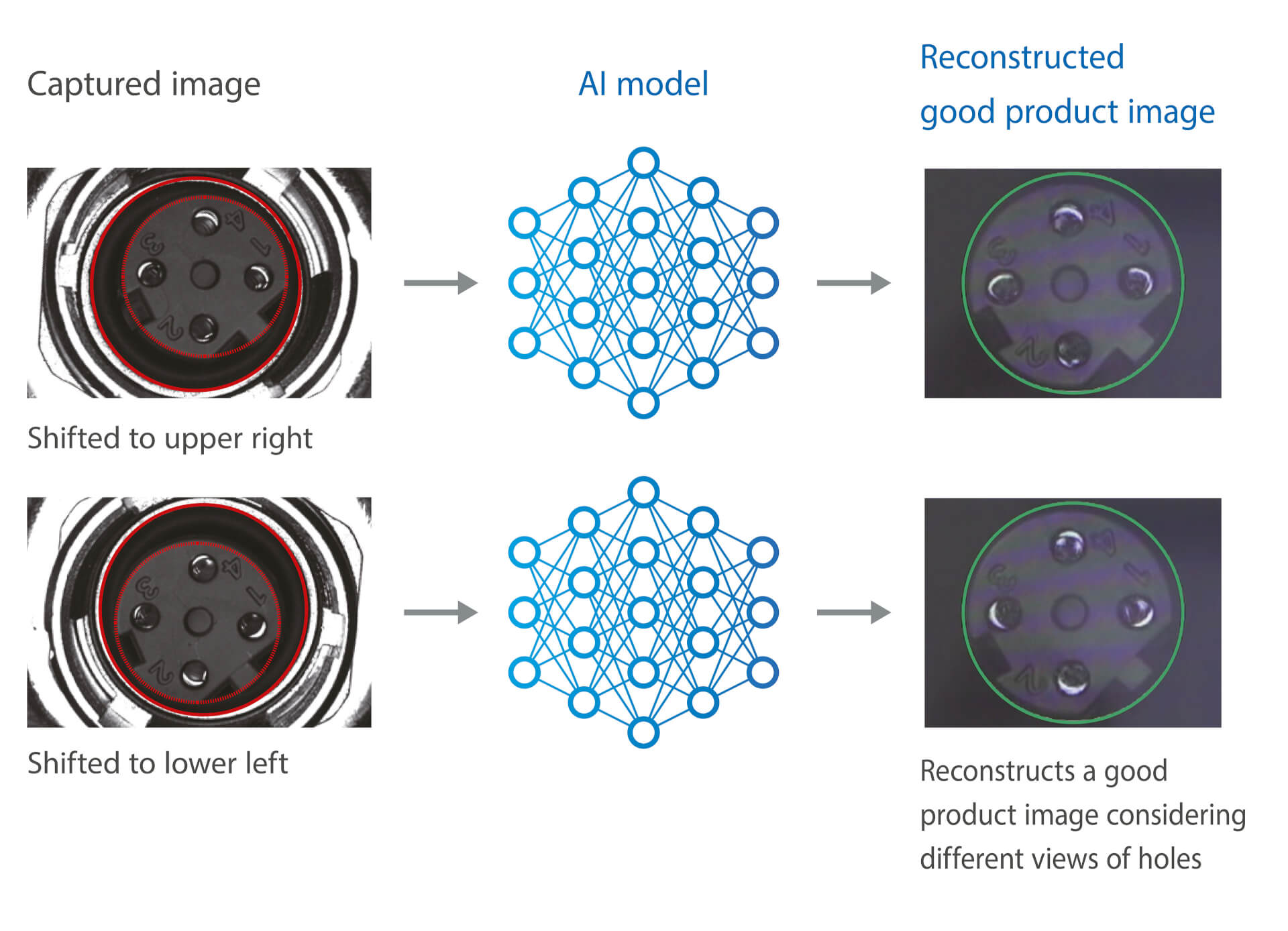

AI Fine Matching

AI fine matching identifies a feature that is not included in good products as a defect. AI learns images of good products with variations and generates an AI Model. Every time an inspection is carried out, AI reconstructs a model that is presumed to be a good product. AI extracts a difference between the reconstructed good product image and a captured image to identify a Defect, reducing over detection..

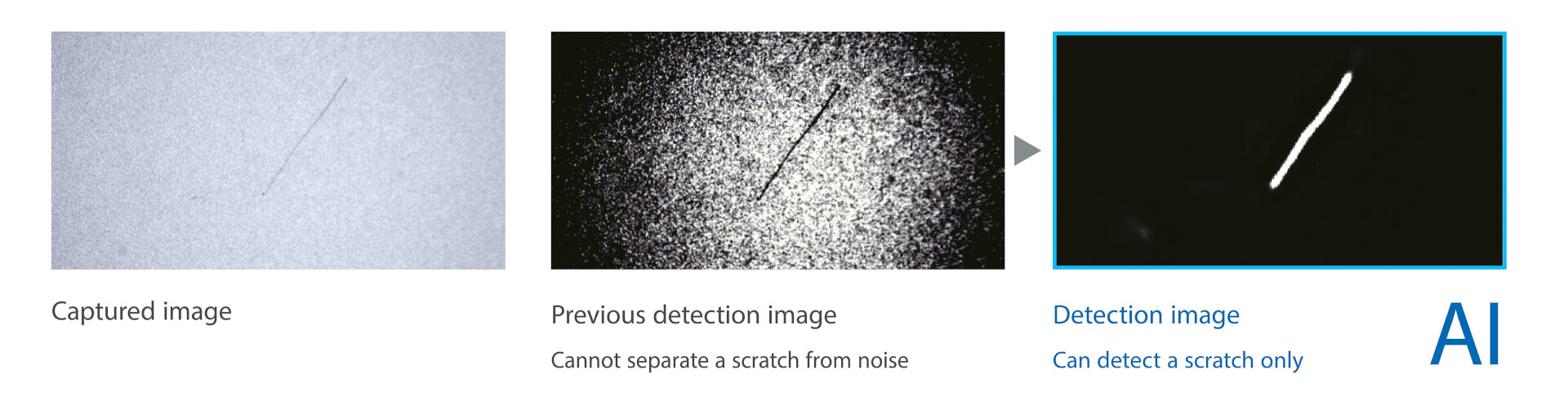

AI Scratch Defect

The latest capabilities of the FH Vision System include an AI-based image filter that reproduces the technique that skilled inspectors use to identify a defect on any product background. Scratches and blemishes that were once difficult to capture can now be identified even without the use of samples or adjustment

Applications

Enhancing detection with Linescan Cameras

Linescan cameras have a significant advantage over area scan cameras when it comes to large, cylindrical or continuously moving objects. The FH supports connection for 4 up to Linescan cameras from 2K to 8K resolution.

Optimized Solutions with Linescan Imaging

Fast moving production lines, curved or cylindrical objects or applications with limited space are ideal for Linescan imaging. Common applications include:

- Label Inspection of cylindrical products that require inspection.

- Continuous inspections on Pick & Place applications or counting applications.

- Defect /surface inspection of EV batteries that require inspection across the full surface of the part.

21 CFR Part 11 & GMP Compliant Ready Vision System

The FH Vision system can be upgraded to support 21 CFR Part 11 & GMP compliance, enabling Life science, pharmaceutical & medical device manufacturers to install vision systems to their production lines to comply with these regulations.

Software Features

- Audit trail report

- Audit trail viewer

- Enhanced password security

- Encrypted files

- User access controls

- Single sign-on ready

- HMI Integration

Digimarc digital watermark decoding

Un-matched decoding on Cylindrical & Flexible Packaging

Appearance inspection of rechargeable battery cells

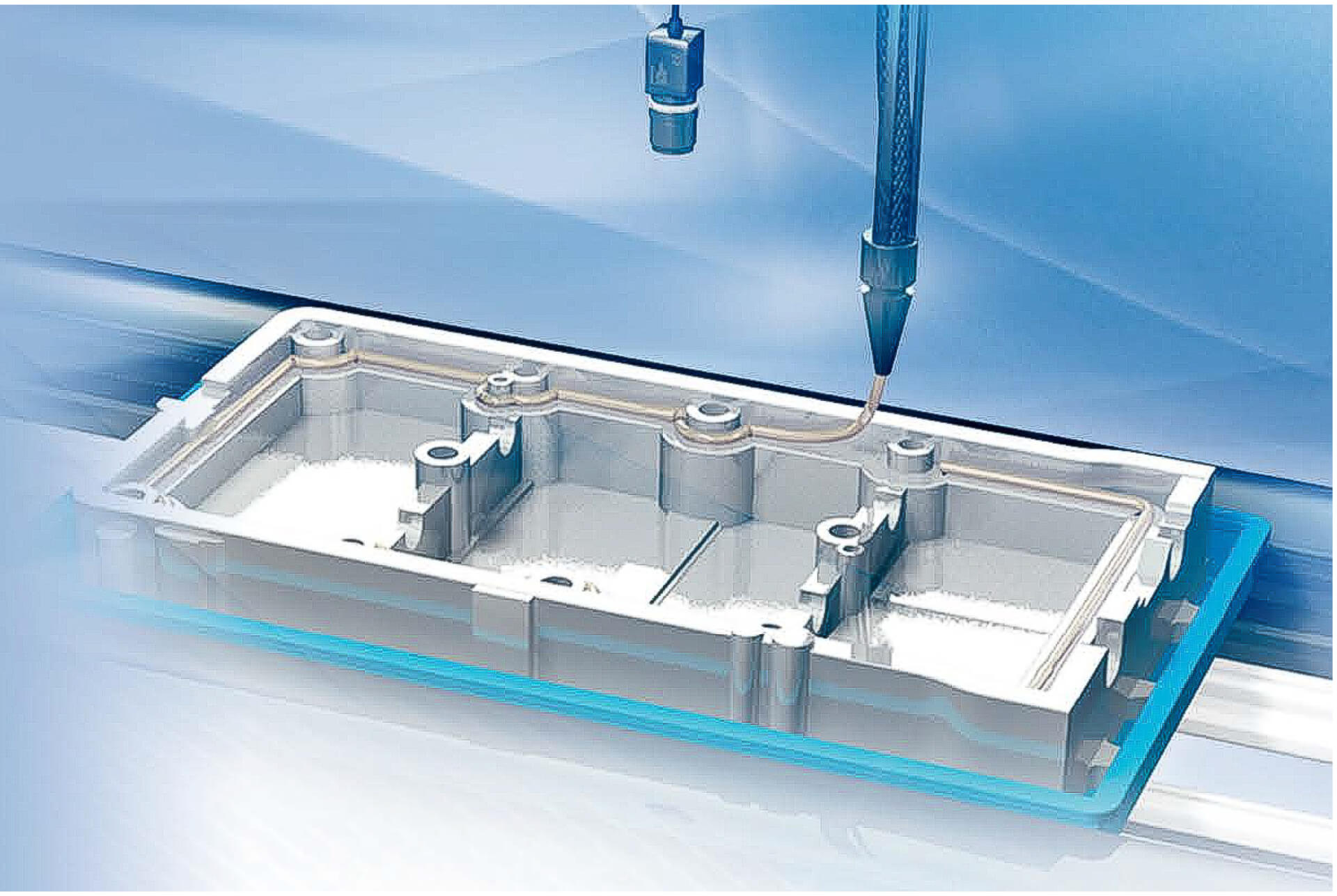

Glue Bead Inspection

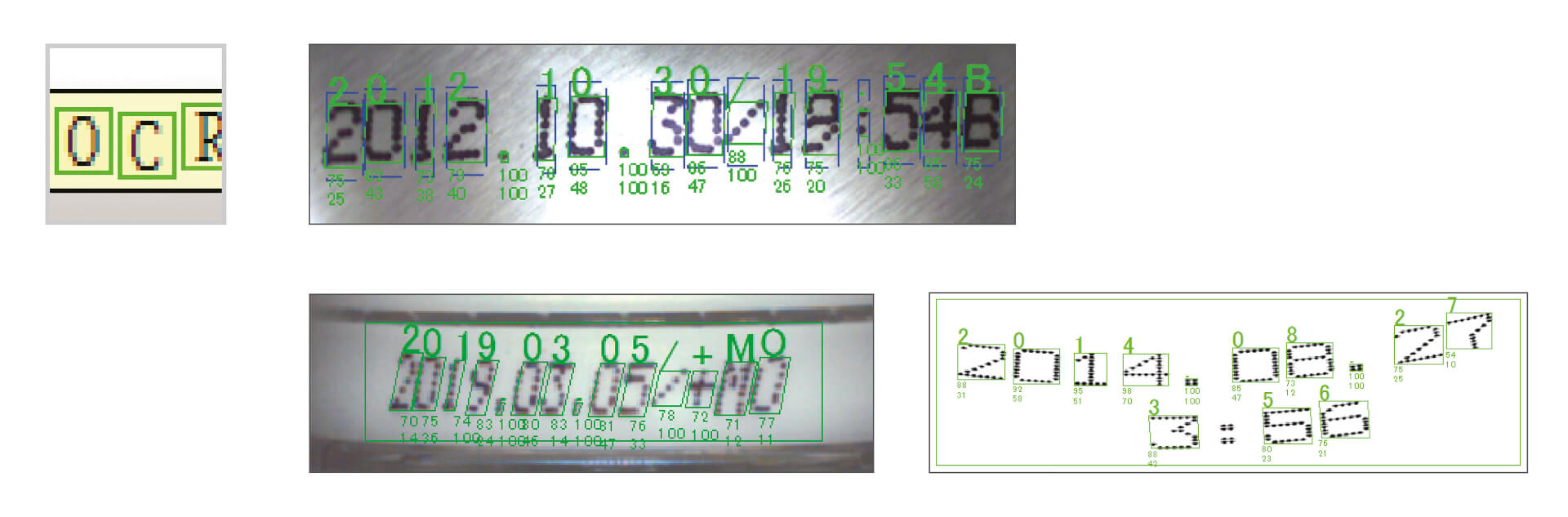

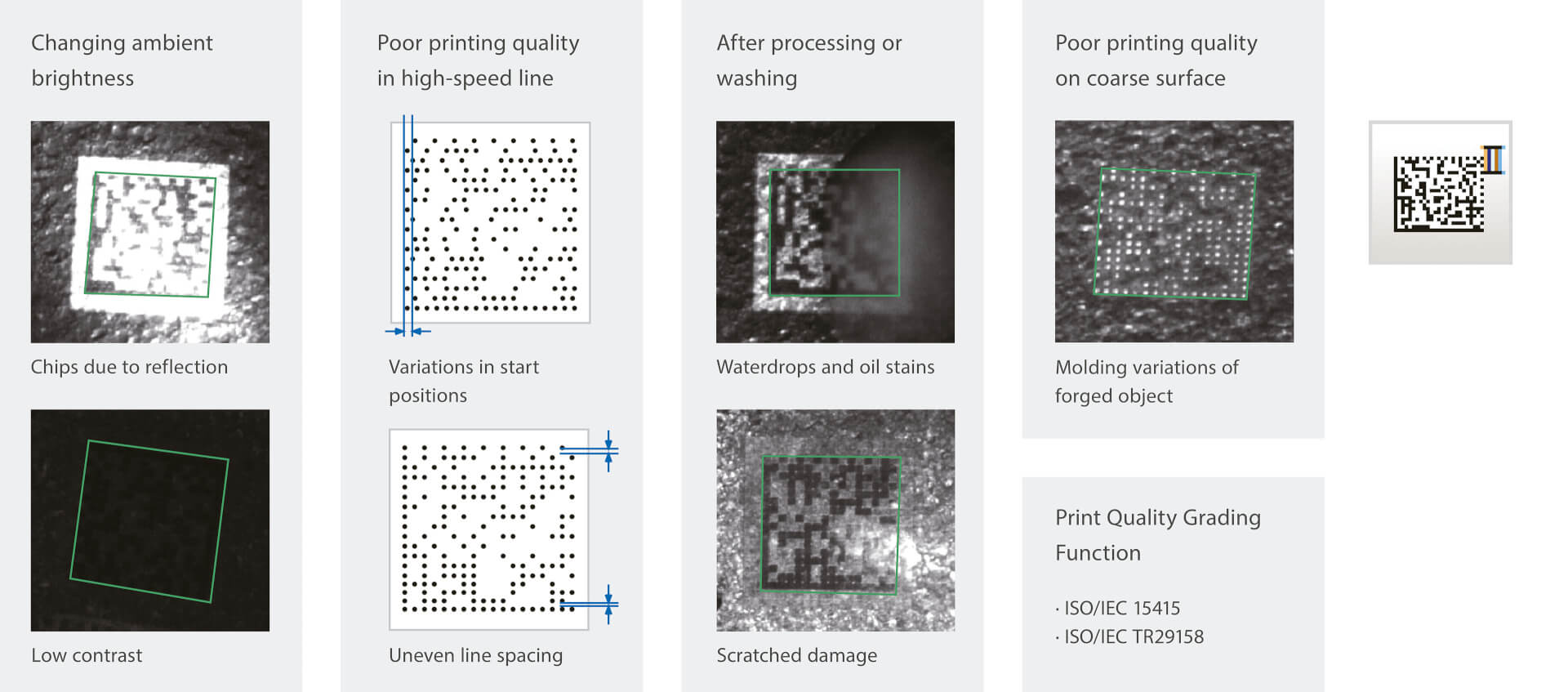

Reliably read difficult to read characters

Lens Selector

Videos

-

FH Vision System from OMRON: AI defect inspection for chips on glass bottles

Stable detection of just the defects, even with workpiece gloss variations.

03:07

FH Vision System from OMRON: AI defect inspection for chips on glass bottles

Stable detection of just the defects, even with workpiece gloss variations.

-

FH Vision System: AI defect inspection of laminated battery tab welding

Stable detection of just the defects, even with workpiece gloss variations.

02:44

FH Vision System: AI defect inspection of laminated battery tab welding

Stable detection of just the defects, even with workpiece gloss variations.

-

FH Vision System from OMRON: AI defect inspection of stator powder coating

Stable detection of just the defects, even with workpiece gloss variations.

03:08

FH Vision System from OMRON: AI defect inspection of stator powder coating

Stable detection of just the defects, even with workpiece gloss variations.

-

3 Step Easy Configuration of AI Defect Inspection FH Vision System from OMRON

OMRON has created the AI defect inspection feature that is easy to use for anyone.

02:47

3 Step Easy Configuration of AI Defect Inspection FH Vision System from OMRON

OMRON has created the AI defect inspection feature that is easy to use for anyone.Specifications & ordering info

| Product | Performance | Processor family | Operating system | Memory | AI Scratch detection filter | AI FineMatching | Number of cameras | Integrated monitor | Communication port(s) | Output type | Application | Description | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

Medium | Intel® Celeron® | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | No | No | 2 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH medium speed & performance controller 2-core, NPN/PNP, 2 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Medium | Intel® Celeron® | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (ECC) | No | No | 4 | No | EtherCAT Slave, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH medium speed & performance controller 2-core, NPN/PNP, 4 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Medium | Intel® Celeron® | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | No | No | 8 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH medium speed & performance controller 2-core, NPN/PNP, 8 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Medium | Intel® Celeron® | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | No | Yes | 2 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH Next generation medium speed & performance controller 2-core, NPN/PNP, 2 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Medium | Intel® Celeron® | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | No | Yes | 4 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH Next generation medium speed & performance controller 2-core, NPN/PNP, 4 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Medium | Intel® Celeron® | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | No | Yes | 8 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH Next generation medium speed & performance controller 2-core, NPN/PNP, 8 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

High | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | Yes | Yes | 2 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, 3D Bin picking, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH high-speed / high performance controller 4-core, NPN/PNP, 2 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

High | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | Yes | Yes | 4 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH high-speed / high performance controller 4-core, NPN/PNP, 4 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

High | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | Yes | Yes | 8 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH high-speed / high performance controller 4-core, NPN/PNP, 8 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

High | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | Yes | Yes | 2 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH Next generation high-speed / high performance controller 8-core, NPN/PNP, 2 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

High | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | Yes | Yes | 4 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH Next generation high-speed / high performance controller 8-core, NPN/PNP, 4 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

High | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 8 GB RAM (non ECC) | Yes | Yes | 8 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH Next generation high-speed / high performance controller 8-core, NPN/PNP, 8 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Very high | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 32 GB RAM (non ECC) | Yes | Yes | 2 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, 3D Bin picking, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH high-speed / high performance / extended storage, controller 4-core, NPN/PNP, 2 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Very high | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 32 GB RAM (non ECC) | Yes | Yes | 4 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH high-speed / high performance / extended storage, controller 4-core, NPN/PNP, 4 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Very high | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 32 GB RAM (non ECC) | Yes | Yes | 8 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH high-speed / high performance / extended storage, controller 4-core, NPN/PNP, 8 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Very high | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 32 GB RAM (non ECC) | Yes | Yes | 2 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH Next generation high-speed / high performance / extended storage, controller 8-core, NPN/PNP, 2 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Very high | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 32 GB RAM (non ECC) | Yes | Yes | 4 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH Next generation high-speed / high performance / extended storage, controller 8-core, NPN/PNP, 4 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Very high | Intel® Core™ i7 | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 32 GB RAM (non ECC) | Yes | Yes | 8 | No | EtherCAT Slave, EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, AI fine matching, AI scratch detection, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH Next generation high-speed / high performance / extended storage, controller 8-core, NPN/PNP, 8 cameras, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Lite | Intel® Atom™ | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 32 GB RAM (non ECC) | No | No | 2 | No | EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, Bead inspection, Code reading, Code verification, Color inspection, Counting, Defect inspection, Measurement inspection, OCR / OCV, Presence / Absence | FH-Lite controller, standard grade, box type, 2 camera, W10 IoT Enterprise LTSC 2019 64bit |

|

|

|

Lite | Intel® Atom™ | Windows 10 IoT Enterprise 2019 LTSC - 64 bit | 32 GB RAM (non ECC) | No | No | 4 | No | EtherNet/IP, Ethernet TCP/IP, PROFINET Slave, Serial RS-232C, USB | PNP/NPN | 2D Robot guidance, Bead inspection, Code reading, Code verification, Counting, Defect inspection, Measurement inspection, OCR / OCV | FH-Lite controller, standard grade, box type, 4 camera, , W10 IoT Enterprise LTSC 2019 64bit |

|

New FH Vision System with industry’s first AI defect detection

The image processing system identifies subtle defects with human-like sensitivity to achieve higher defect detection rates.

We’re Here to Help

Got a question? Our specialists are ready to assist you every step of the way.

Ota minuun yhteyttä FH Vision System

Kiitos yhteydenotostasi. Otamme teihin yhteyttä mahdollisimman pian.

Meillä on teknisiä ongelmia. Emme ole pystyneet vastaanottamaan lomakettasi. Pahoittelemme ja pyydämme yrittämään uudelleen myöhemmin.

DownloadTarjous FH Vision System

Tällä lomakkeella voit pyytää tarjouksen valitsemastasi tuotteesta. Täytäthän kaikki *-merkityt kentät. Henkilökohtaisia tietojasi käsitellään luottamuksellisesti.

Kiitos tarjouspyynnöstä. Toimitamme tarvittavat tiedot teille mahdollisimman pian.

Meillä on teknisiä ongelmia. Emme ole pystyneet vastaanottamaan lomakettasi. Pahoittelemme ja pyydämme yrittämään uudelleen myöhemmin.

DownloadDownloads

Related Products

Need assistance?

We’re here to help! Reach out, and our specialists will assist you in finding the best solution for your business.

Ota minuun yhteyttä FH Vision System

Kiitos yhteydenotostasi. Otamme teihin yhteyttä mahdollisimman pian.

Meillä on teknisiä ongelmia. Emme ole pystyneet vastaanottamaan lomakettasi. Pahoittelemme ja pyydämme yrittämään uudelleen myöhemmin.

DownloadTarjous FH Vision System

Tällä lomakkeella voit pyytää tarjouksen valitsemastasi tuotteesta. Täytäthän kaikki *-merkityt kentät. Henkilökohtaisia tietojasi käsitellään luottamuksellisesti.

Kiitos tarjouspyynnöstä. Toimitamme tarvittavat tiedot teille mahdollisimman pian.

Meillä on teknisiä ongelmia. Emme ole pystyneet vastaanottamaan lomakettasi. Pahoittelemme ja pyydämme yrittämään uudelleen myöhemmin.

Download