Customer References

Explore how our industrial automation solutions have helped our customers solve challenges and improve productivity, safety and efficiency. Leading the way to the factory of the future where humans and machines work side-by-side in harmony

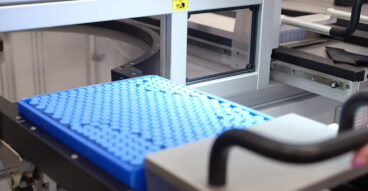

An innovative feeding solution for cable harness production

27. marraskuuta 2025 OMRON and ERKO have developed an innovative, fully automated workstation for cable harness production.

CP Foods UK automates poultry packing with OMRON & Gripple Automation

08. syyskuuta 2025 High-speed, high-quality packaging line helps meet retail demands

Korteks achieves digital transformation in textured yarn packaging with OMRON automation solutions

28. elokuuta 2025 The project integrated OMRON PLCs, motion control, sensors, and safety systems, engineered with Sysmac Studio software

Maluka speeds up food cartoning process with OMRON servo drives

18. elokuuta 2025 RaceTrack Function Block simplifies complex motion control

AJ Vaccines implements a prototype of vision-based vial counting

04. elokuuta 2025 To further strengthen data integrity at vaccine manufacturer AJ Vaccines, OMRON has successfully developed and deployed a proof of concept for the automatic counting of vials in AJ Vaccines’ production.

Mackle upgrades pet food formats with Clevertech and OMRON

04. heinäkuuta 2025 Pouch packaging achieves an estimated 50% productivity increase

OMRON mobile robots help improve the flow at Danfoss Power Solutions

02. heinäkuuta 2025 Danfoss replaced its traditional warehouse with a fully automated solution that eliminates manual lifting. OMRON mobile robots now transport parts seamlessly, with zero human handling.

Brillopak develops a fully automated pick and pack machine

20. maaliskuuta 2025 Brillopak’s UniPAKer P160 pick-and-place machine is designed to meet the high standards of the food manufacturing industry.

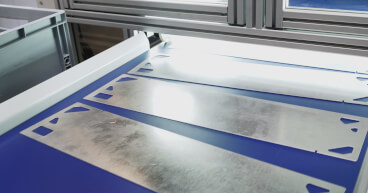

MPA Technology GmbH automates intralogistics for a precision engineering company with OMRON robotics

21. helmikuuta 2025 A customized stacking and unstacking solution ensures the smooth movement of small load carriers (KLTs), improving operational efficiency. The system eliminates long walking distances for employees, supports order management via an intuitive interface, and allows for easy expansion of the AMR fleet. This approach optimizes production flow while freeing employees for higher-value tasks.

ESE International automates first aid kit production with OMRON’s cobot

03. joulukuuta 2024 ESE International B.V., a leading provider of medical equipment including first aid kits and evacuation materials, faced a challenge in their production process. The task of printing on first aid kits involved manual labour, where an operator was required to insert each plastic box into a printer, wait for the printing to complete, and then place the finished box back on a pallet. This process was not only monotonous for employees but also inefficient, leading to unnecessary labour costs and wasted time. ESE International sought to automate this repetitive task, aiming to save on costs, improve efficiency, and reduce downtime during non-working hours. The ultimate goal was to allow the cobot to handle the process autonomously, including running overnight, while saving resources.

Werfen responds to demands from clinical laboratories with vertical labelling of vials

12. marraskuuta 2024 For the supply of reagents to drug toxicology laboratories, Werfen has implemented a new automated machine built by MACCO in collaboration with OMRON and Marini Pandolfi.

FG Robosys

25. syyskuuta 2024 FG Robosys, a leader in providing robotic solutions for the cosmetic and personal care industries, decided to enhance their robotic bottling line to improve efficiency and reduce changeover times at their customers’ production facilities.

Teklas enhances intralogistics efficiency with Peak Porter and OMRON Mobile Robots

09. heinäkuuta 2024 Teklas, a global leader in fluid management systems, operates 12 factories across 6 countries, continually advancing its position in the automotive industry. Teklas specializes in advanced thermal and fluid management solutions for the automotive industry. Their offerings include systems for fluid circulation, thermal management, and air conditioning, serving major automotive manufacturers globally. With a clear focus on operational efficiency, Teklas has taken significant steps in modernizing its intralogistics through collaboration with Peak Porter. Peak Porter specializes in automated intralogistics solutions for internal logistics processes, optimizing storage, transport, and handling operations. This collaboration has allowed Teklas to automate its storage processes, using autonomous mobile robots (AMRs) from OMRON. By integrating these technologies, Teklas has successfully improved the sustainability and efficiency of its facilities.By opting for robotic technologies in production and storage processes, Teklas has succeeded in minimizing errors and reducing manual labour. As a result, disruptions and issues in operations have been largely eliminated. The company is also extremely satisfied with the results obtained from the integration of automatic intralogistics systems provided by Peak Porter.

SolarEdge e-Mobility transforms production processes

13. lokakuuta 2023 FasThink solution streamlined warehouse operations with autonomous mobile robots

Autonome mobile Roboter bringen Materialfluss bei Polar Semiconductor auf Touren

12. heinäkuuta 2023 US-Chiphersteller optimiert Materialtransport und Effizienz

Operators, cobots and mobile robots work in harmony: Grupo Antolin automates loading and transport of car interior components

08. helmikuuta 2023 OMRON robots help Grupo Antolin achieve a modernized and sustainable vehicle interior factory where people and machines work in harmony.

Real time data monitoring ensures defect-free relays

30. tammikuuta 2023 OMRON Automotive Electronics Italy has upgraded its production line of Power and G8HN relays for the automotive market.

Virtual Twins in the Automotive Industry: Innovation Boost for Fuel Cell Production

28. marraskuuta 2022 “One for all, all for one.” This motto of the “Three Musketeers” from Alexandre Dumas' novel dates back to 1844, and yet it has not lost its relevance over the years. Three companies that count themselves among the innovation leaders in their industries have now joined forces to drive the future of mobility, or more precisely the fuel cell. As a strong team of three, the automation experts from OMRON, the virtual twin specialists from Dassault Systèmes, and the production and digitization professionals from VAF GmbH are pooling their expertise in their respective fields.

FasThink optimizes Garnet's intralogistics with mobile robots

02. marraskuuta 2021 Garnet relies on FasThink to innovate its logistics and production processes.

Cisel ensures traceability, safety and quality by testing printed circuit boards with a cobot

17. kesäkuuta 2021 Cisel is an Italian company that specialises in the design and production of flexible printed circuit boards (PCBs) for the automotive, civil engineering and manufacturing industries. The company recently chose an OMRON TM5 collaborative robot (cobot) to automate the electrical testing of boards used in the power steering system of a leading automotive manufacturer.

Cobot ensures precise assembly of magnets for LITMAT’s drain plugs

03. kesäkuuta 2021 Collaborative robots (cobots) are being used more and more extensively, in a range of different industries and across a wide variety of applications. They can make a significant difference to the efficiency and productivity of the production cycle. One company that is enjoying such benefits is LITMAT SpA.

Moving to e-mobility: seven tips for success

08. syyskuuta 2020 The automotive industry throughout Europe is changing. It’s been badly hit by the Covid-19 pandemic, which has exacerbated declining sales. And there have been other problems. For instance, the Center for Automotive Research (CAR) forecasts that German vehicle manufacturers and suppliers could lose a quarter of their total workforce by 2030. A similarly gloomy picture is also emerging in the UK. Offsetting this is a growing demand for electric cars, which could lead to many new jobs being created.

Energizing European battery cell production

01. toukokuuta 2020 What can European automotive companies do to future-proof their production lines, especially in relation to battery manufacturing? Robotics, automated quality control and artificial intelligence (AI) can help companies to tackle the strong competition they are facing from Asia.

Mobile robots smarten up Toyota’s new parts centre

28. huhtikuuta 2020 Intelligent robots and sophisticated design are helping Toyota to achieve a higher level of efficiency at its new warehouse in Sydney, Australia.

CP Foods UK automates poultry packing with OMRON & Gripple Automation

08. syyskuuta 2025 High-speed, high-quality packaging line helps meet retail demands

Maluka speeds up food cartoning process with OMRON servo drives

18. elokuuta 2025 RaceTrack Function Block simplifies complex motion control

Mackle upgrades pet food formats with Clevertech and OMRON

04. heinäkuuta 2025 Pouch packaging achieves an estimated 50% productivity increase

Brillopak develops a fully automated pick and pack machine

20. maaliskuuta 2025 Brillopak’s UniPAKer P160 pick-and-place machine is designed to meet the high standards of the food manufacturing industry.

FG Robosys

25. syyskuuta 2024 FG Robosys, a leader in providing robotic solutions for the cosmetic and personal care industries, decided to enhance their robotic bottling line to improve efficiency and reduce changeover times at their customers’ production facilities.

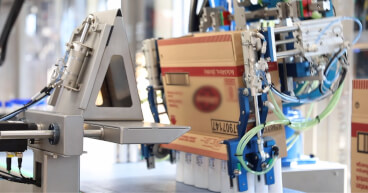

Automated Solution for Case Erector Loading: Coboloader from Inser Robótica

14. kesäkuuta 2024 Improving the end-of-line efficiency and ergonomics with a collaborative robotic cell

Watch video on an innovative anti-sloshing solution for soup and ready meal packaging

25. huhtikuuta 2024 Argo offers a significant increase in productivity by 30-40%, ensuring high seal quality and hygiene standards. With reduced machine contamination and minimized tray waste, it contributes to sustainability efforts. Italian Pack's customizable solutions, coupled with OMRON's technical expertise, enable access to new customer segments with high standards, strengthening their market position. Argo represents a successful collaboration, delivering tangible benefits to manufacturers of soups, sauces, and ready meals.

Picomel looks to the future with a visionary production line

17. tammikuuta 2024 Vertical factory saves space and energy while reducing waste

Ricciarelli ensures the perfect closure of spaghetti packaging

28. elokuuta 2023 The new horizontal cartoning machine for long pasta utilizes OMRON's vision systems to verify the effective closure of the packaging and perfect OCR/OCV marking.

Bandall streamlines banding machines for sustainable packaging

07. kesäkuuta 2023 One stand-alone solution with OMRON sensors covers various banding needs

Keeping up with high demand for vegan ice cream with collaborative robotics

26. toukokuuta 2023 Ice Bakers automates end-of-line packaging process with an OMRON TM cobot

MACCO boosts productivity and innovation in packaging lines with OMRON SCARA i4L robot

18. huhtikuuta 2023 Optimizing packaging processes for cosmetic, pharmaceutical, and nutraceutical products

AJ Vaccines implements a prototype of vision-based vial counting

04. elokuuta 2025 To further strengthen data integrity at vaccine manufacturer AJ Vaccines, OMRON has successfully developed and deployed a proof of concept for the automatic counting of vials in AJ Vaccines’ production.

ESE International automates first aid kit production with OMRON’s cobot

03. joulukuuta 2024 ESE International B.V., a leading provider of medical equipment including first aid kits and evacuation materials, faced a challenge in their production process. The task of printing on first aid kits involved manual labour, where an operator was required to insert each plastic box into a printer, wait for the printing to complete, and then place the finished box back on a pallet. This process was not only monotonous for employees but also inefficient, leading to unnecessary labour costs and wasted time. ESE International sought to automate this repetitive task, aiming to save on costs, improve efficiency, and reduce downtime during non-working hours. The ultimate goal was to allow the cobot to handle the process autonomously, including running overnight, while saving resources.

Werfen responds to demands from clinical laboratories with vertical labelling of vials

12. marraskuuta 2024 For the supply of reagents to drug toxicology laboratories, Werfen has implemented a new automated machine built by MACCO in collaboration with OMRON and Marini Pandolfi.

Empowering operators, enhancing efficiency:

14. marraskuuta 2023 Sanofi automates palletizing with collaborative robots

Mobile robots streamline internal logistics at HIPRA

13. heinäkuuta 2023 Autonomous mobile robots increase the flexibility, efficiency, and productivity of material transport.

OMRON vision system ensures uniform tablet coating at IMA

18. lokakuuta 2022 IMA Group raises pharmaceutical industry standards with vision

Steierl-Pharma modernizes and optimizes labelling processes with inspection technology

02. marraskuuta 2021 Hardly any other industry is subject to such high-quality requirements and legal regulations as pharmaceutical companies.

Automated pipetting solution ensures rapid evaluation of Covid-19 samples

09. heinäkuuta 2021 GriPS Automation GmbH and D&T engineering GmbH have developed a solution to streamline pipetting, reducing processing time from one hour to ten minutes per plate.

Älykäs robotiikka mahdollistaa koronaviruksen nopeiden vasta-ainetestien joustavan tuotannon Senovassa

29. tammikuuta 2021 Saksalainen lääketieteellisen teknologian asiantuntija Senova kehitti tulevaisuuden tehtaan yhteistyössä OMRONin ja Kraus Maschinenbau GmbH:n kanssa.

Quiet and efficient robotics solution enables flexible bottle production at Ganahl AG

22. heinäkuuta 2019 Ganahl, Swiss manufacturer of bottles for the cosmetics, food and pharmaceutical industries opts for eCobra robots, feeding solution, vision technology as well as NX1 controller for holistic robotics support from Omron.

Automated Solution for Case Erector Loading: Coboloader from Inser Robótica

14. kesäkuuta 2024 Improving the end-of-line efficiency and ergonomics with a collaborative robotic cell

MACCO boosts productivity and innovation in packaging lines with OMRON SCARA i4L robot

18. huhtikuuta 2023 Optimizing packaging processes for cosmetic, pharmaceutical, and nutraceutical products

Autonomous mobile robots simplify intralogistics at Diva International

04. maaliskuuta 2021 Large companies are increasingly turning to robotics to streamline manual processes in factories and warehouses. One example is Diva International, based in Umbria, Italy. Diva wanted to transform its system for transporting wet wipes from its production facility to a palletising island in the same warehouse. Through its facilities management provider, FM Vision, it developed a new, automated system using five OMRON autonomous mobile robots (AMRs) and OMRON’s Sysmac NJ machine controller. This has led to a safer, more efficient and more flexible process.

Fast and safe transport on the factory floor

18. tammikuuta 2021 Improved efficiency and seamless material supply: in Austria, Philips is automating material transport by using AMRs from OMRON.

High-speed manufacturing line with mobile robots ensures customisation in seconds

08. huhtikuuta 2020 The oral hygiene manufacturer TePe has installed a new manufacturing line to replace its manual handling and quality inspection at their factory in Malmö, Sweden.

An innovative feeding solution for cable harness production

27. marraskuuta 2025 OMRON and ERKO have developed an innovative, fully automated workstation for cable harness production.

Korteks achieves digital transformation in textured yarn packaging with OMRON automation solutions

28. elokuuta 2025 The project integrated OMRON PLCs, motion control, sensors, and safety systems, engineered with Sysmac Studio software

OMRON mobile robots help improve the flow at Danfoss Power Solutions

02. heinäkuuta 2025 Danfoss replaced its traditional warehouse with a fully automated solution that eliminates manual lifting. OMRON mobile robots now transport parts seamlessly, with zero human handling.

MPA Technology GmbH automates intralogistics for a precision engineering company with OMRON robotics

21. helmikuuta 2025 A customized stacking and unstacking solution ensures the smooth movement of small load carriers (KLTs), improving operational efficiency. The system eliminates long walking distances for employees, supports order management via an intuitive interface, and allows for easy expansion of the AMR fleet. This approach optimizes production flow while freeing employees for higher-value tasks.

Streamlining order fulfilment in logistics operations: Distributor of electrical motors puts a mobile robot into action

31. toukokuuta 2024 Brd. Klee A/S, a Danish distributor of electrical motors, partnered with Ølgod Elektro to implement an autonomous mobile robot (AMR) solution from OMRON, aiming to optimize their logistics processes. By integrating the OMRON LD250 mobile robot, Brd. Klee significantly increased productivity, enhanced flexibility, and improved workplace safety. The solution streamlined order fulfilment, reduced manual labour, and ensured a smoother internal goods flow. With seamless integration and collaboration, Brd. Klee achieved operational excellence, setting the stage for future development and innovation.

Manufacturing excellence meets automation expertise:

29. toukokuuta 2024 HB-Maschinenbau relies on technology from OMRON

Enhancing safety and efficiency:

23. elokuuta 2023 OMRON's new M1 inverter transforms tile manufacturing

Laser Quality Markings automates repetitive machine tending

03. elokuuta 2023 Moving from manual labour to collaborative automation frees up operators for creative work

Mobile robots streamline internal logistics at HIPRA

13. heinäkuuta 2023 Autonomous mobile robots increase the flexibility, efficiency, and productivity of material transport.

Tecno-Elèctric Girona (TEG) becomes specialized OMRON Safety Integrator

08. helmikuuta 2023

Hanover Displays automates PCBA testing with cobots

31. tammikuuta 2022 UK-based Hanover Displays Limited needed a new system for testing printed circuit board assemblies (PCBAs) and selected OMRON TM cobots for the job, supplied and installed by Absolute Robotics, part of the Absolute Automation Group.