Customer References

Explore how our industrial automation solutions have helped our customers solve challenges and improve productivity, safety and efficiency. Leading the way to the factory of the future where humans and machines work side-by-side in harmony

Autonome mobile Roboter bringen Materialfluss bei Polar Semiconductor auf Touren

12. heinäkuuta 2023 US-Chiphersteller optimiert Materialtransport und Effizienz

Bandall streamlines banding machines for sustainable packaging

07. kesäkuuta 2023 One stand-alone solution with OMRON sensors covers various banding needs

Keeping up with high demand for vegan ice cream with collaborative robotics

26. toukokuuta 2023 Ice Bakers automates end-of-line packaging process with an OMRON TM cobot

MACCO boosts productivity and innovation in packaging lines with OMRON SCARA i4L robot

18. huhtikuuta 2023 Optimizing packaging processes for cosmetic, pharmaceutical, and nutraceutical products

Campari Group improves safety worldwide with OMRON Safety

14. maaliskuuta 2023 Putting people first: Campari Group improves safety worldwide with OMRON Safety Services. Empowering employees to promote safety from the ground up.

Operators, cobots and mobile robots work in harmony: Grupo Antolin automates loading and transport of car interior components

08. helmikuuta 2023 OMRON robots help Grupo Antolin achieve a modernized and sustainable vehicle interior factory where people and machines work in harmony.

Tecno-Elèctric Girona (TEG) becomes specialized OMRON Safety Integrator

08. helmikuuta 2023

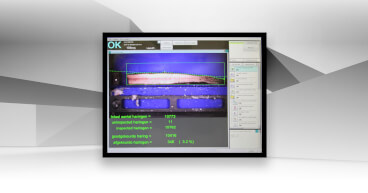

Real time data monitoring ensures defect-free relays

30. tammikuuta 2023 OMRON Automotive Electronics Italy has upgraded its production line of Power and G8HN relays for the automotive market.

Virtual Twins in the Automotive Industry: Innovation Boost for Fuel Cell Production

28. marraskuuta 2022 “One for all, all for one.” This motto of the “Three Musketeers” from Alexandre Dumas' novel dates back to 1844, and yet it has not lost its relevance over the years. Three companies that count themselves among the innovation leaders in their industries have now joined forces to drive the future of mobility, or more precisely the fuel cell. As a strong team of three, the automation experts from OMRON, the virtual twin specialists from Dassault Systèmes, and the production and digitization professionals from VAF GmbH are pooling their expertise in their respective fields.

World’s first five-lane bag-in-box machine from Pro Project Machinery

08. marraskuuta 2022 New energy-efficient full servo machine boosts production by 25%

Vetipak enjoys the sweet taste of success thanks to robotics

08. marraskuuta 2022 Packaging solution with robotics integrated control ensures scalable processes and high-quality contract manufacturing in FMCG

OMRON vision system ensures uniform tablet coating at IMA

18. lokakuuta 2022 IMA Group raises pharmaceutical industry standards with vision

Agile cobot palletiser from Reeco Automation

14. kesäkuuta 2021 60% smaller footprint and costing up to 50% less compared to conventional robot palletisers

Four top tips for automation projects in the food and beverage industry

22. helmikuuta 2021 A challenge accelerated by the Coronavirus pandemic has seen producers having to juggle between longer term range proliferation centred on consumer demands, and range (SKU’s) reduction caused by retailers and consumers rapidly changing buying habits. Companies that break new ground by using innovative technologies not only gain agility but also reduce scrap, contamination risk, waste and losses.

Novio Packaging reaches new levels of quality with machine vision

12. tammikuuta 2021 Inline quality inspection ensures defect-free production of bottles

Unique high-speed seed counting and packing solution by Micron Milling

22. lokakuuta 2020 Overcoming the challenge of accuracy for a large retail group

Automated fish filleting solution ensures quality and cost efficiency at Seafood Parlevliet

01. syyskuuta 2020 Raw brined herring is an acquired taste and holds a special place in many Dutch people’s hearts. Combined with a sprinkling of raw onions, many say that taking a big bite of the herring vertically, holding onto the tail of the fish is the only right way to eat it. However, this poses special requirements during the filleting process, as the tail of the fish needs to be preserved, in addition to demanding quality requirements.

Collaborative robots enhance productivity at CLECA

06. elokuuta 2020 Palletizing process automated with OMRON TM12 cobots

Factory automation: four tips for the future of food & beverage manufacturing

16. heinäkuuta 2020 The coronavirus pandemic has posed major challenges to organisations of all types and sizes. In the food and commodity industry, companies have faced significantly reduced consumption and disrupted supply chains, while at-home consumption increased, and out-of-home consumption came near to a standstill. But how can manufacturers adapt their business strategies and production processes both now and in the longer term? The pandemic may provide an opportunity for rethinking outdated processes and procedures and enhancing them with concepts such as innovative robotics, sensor technology and holistic automation strategies.

Automation with robotics increases production by 40% at BOLÇİ

28. toukokuuta 2020 Turkish chocolate manufacturer BOLÇİ needed to meet its promise of delivering chocolate products that are ‘untouched by human hand’. Omron and Innovas joined forces to commission a line of three Omron robots in the packaging section of the factory’s production line, with the aim of enhancing production quality and reducing labour costs.

Autonomous bin picking with a collaborative mobile robot

16. lokakuuta 2019 Our TM collaborative robot provides a unique solution to easily automate applications such as picking and packing that, traditionally performed by humans, have been challenging to automate. As part of the TM series launch, we also released a mobile-compatible model, which seamlessly integrates into Omron’s LD series autonomous mobile robot. Combined with a 3D vision camera mounted directly onto the collaborative robot, this enables for example e-commerce companies to automate more complex tasks. This includes pick and place of various items onto a tray or container, as well as connecting production processes with the autonomous mobile robots for flexible manufacturing and materials handling.