Quality Manufacturing

Quality manufacturing processes ensure that products consistently meet customer expectations and regulatory standards while maintaining brand reputation. High-quality manufacturing reduces waste, minimizes rework, and enhances operational efficiency, leading to significant cost savings over time. It also builds trust and loyalty among customers thanks to delivering reliable and safe products. Prioritizing quality is key also in continuous improvement within the production process.

At OMRON, we support quality in manufacturing in three levels, on product quality, packaging quality and data integrity. This approach ensures that every stage of the manufacturing process —before, during, and after primary packaging— adheres to the highest standards of quality, reliability, and sustainability.

We ensure reliability in products, packaging, and data throughout the manufacturing process, as well as extending to logistics, distribution, and recovery/recycling efforts. By promoting quality assurance, waste reduction and operational excellence, we also contribute to circularity and sustainability.

Quality manufacturing in three levels

Zero defects with adaptive inspection

AI-based defect detection solution performs like a skilled inspector, enabling automated detection of subtle defects, agile workflows, and continuous production during personnel shortages.

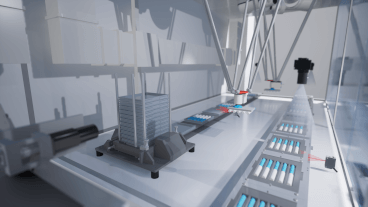

Accurate part recognition with 3D robot vision system

The 3D measurement and recognition technologies enable high-speed part detection in approximately 0.4 seconds. With cameras installed directly at the robot arms, blind spots can be reduced.

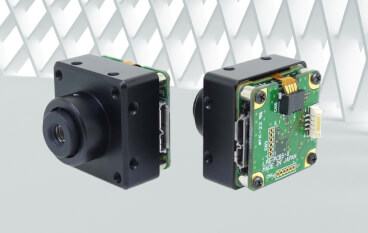

Detect invisible defects with area scan cameras

Identify defects such as contamination, cracks, or variations in composition by analyzing how materials absorb or reflect SWIR light, making it ideal for non-destructive quality inspection.

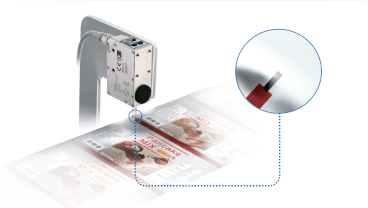

Colour mark detection for a variety of materials

Colour mark sensors detect subtle colour differences under various conditions. The detect colour marks on a variety of packaging materials including highly reflective materials, as well as help optimize initially set parameters to adjust to changes in manufacturing lots.

Transparent detection with sensing solutions

Sensing solutions ensure precise detection, counting, and positioning of transparent objects like films, vials, and syringes, from individual items to pallets. Integrating sensors, actuators, components, HMIs, and controllers for comprehensive production line accuracy.

Perfect sealing with AI-driven temperature control

Improper airtight sealing can spoil products, harm consumer health, and damage brand reputation. AI-driven technology from OMRON ensures precise sealing with real-time temperature control, achieving zero defects and waste.

Quality Inspection Solutions

Whether it be vials, syringes, or cartridges, we have developed a comprehensive portfolio of quality inspection applications - such as empty container inspection, stopper position, crimp control, particle detection or robot guidance, all compliant with FDA 21 CFR Part 11 software.

Avoiding recalls with automation solutions

Product recalls are caused by issues such as poor sealing, labeling errors, or incorrect product coding. Our automation solutions help reduce these risks, ensuring quality and compliance while protecting brand value.

Code quality verification

The barcode or 2D code is the key that unlocks data collection in traceability systems. The quality of the code is the key process parameter to guarantee a reliable traceability system.

Traceability in manufacturing

Traceability plays a pivotal role in modern manufacturing, enabling the meticulous tracking and monitoring of products and components throughout their lifecycle.

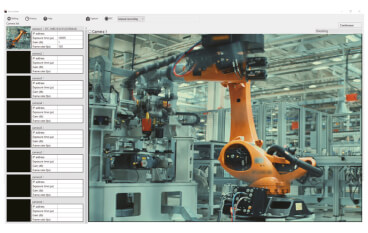

Barcode reading at its best

Barcode readers and smart cameras ensure reliable high-speed decoding of damaged symbols. Combined with software, they handle traceability, quality control, and vision inspection tasks.

Digital watermark decoding for quality and traceability

Digimarc digital watermark decoding on FH machine vision systems and FHV7 smart cameras provides a versatile solution to ensure the correct packaging is used, achieving production speeds of over 2,000 parts per minute.

Quality manufacturing ensures:

-

Consistent quality and compliance:

With products that meet customer expectations, regulatory standards, and maintain brand reputation.

-

Operational efficiency:

Reduced waste, minimized rework, and enhanced production efficiency for improved quality and sustainability.

-

Customer trust:

Reliable, safe products that build lasting trust and satisfaction among customers.

-

Sustainability and circularity:

Waste reduction and quality assurance across manufacturing, logistics, and recycling.

Quality manufacturing technology

Customer References, Examples and Related Articles

Ricciarelli ensures the perfect closure of spaghetti packaging

Ricciarelli's new horizontal cartoning machine for long pasta utilizes OMRON's vision systems to verify the effective closure of the packaging and perfect OCR/OCV marking.

Werfen responds to demands from clinical laboratories with vertical labelling of vials

Werfen’s new automated machine, built with MACCO, OMRON, and Marini Pandolfi, uses SCARA robots and vision systems for precise test tube handling and labelling.

Manufacturing excellence meets automation expertise

HB-Maschinenbau and OMRON automate construction manufacturing with robotics and vision, improving productivity, accuracy, and enabling employees to focus on strategic tasks.