Simulation: from concept to virtual twin

Julkaistu 04. kesäkuuta 2025: Industry 4.0

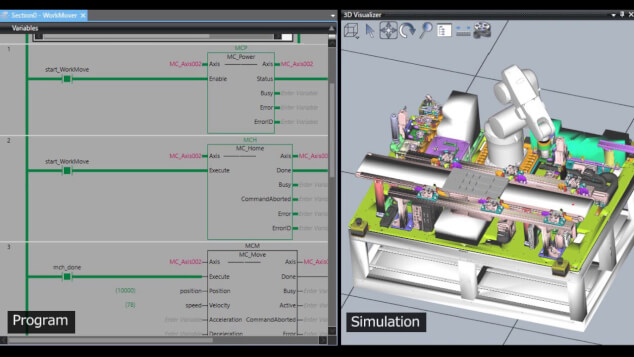

Simulation: from concept to virtual twin

How can manufacturers harness the power of simulation to get real-world design right first time? The concept of using simulation to inform factory design has been around for years, even predating computers. The earliest examples of simulation were physical models that allowed engineers to test processes and designs on a small scale before scaling them up. Whilst the same underlying principles still apply, nowadays, simulation takes place in the virtual environment. This provides a far greater capacity to build complex processes for testing the effect of variables on outcomes; AI-based technologies have been instrumental in achieving this level of flexibility and sophistication.Simulation without boundaries

Simulation strategies

Sysmac Studio: an integrated development environment

Real benefits of virtual simulation

Simulation is a cornerstone of the digital factory. There are so many ways in which it can bring real benefits, from facilitating failure mode and effects analysis that can inform servicing strategies, to enabling parallelisation for performance optimisation and accelerating time to market by shortening planning and design cycles by up to 25% and more.

For the automotive industry, where product lifecycles are shrinking and innovation cycles are accelerating, simulation provides the agility needed to stay competitive. For example, a virtual twin of an electric vehicle battery production line will allow manufacturers to test workflows, optimise material handling and identify potential bottlenecks before investing in equipment.

In the cosmetics industry, where product design needs to consider seasonal trends, regional preferences and ingredient availability, simulation tools can test different formulations and manufacturing setups before physical trials are undertaken.

Through partnerships, OMRON brings new value propositions to manufacturers who want to explore advanced simulation approaches. Combining IT expertise and OMRON’s industrial automation knowhow, these collaborations allows for the open and fast exchange of real-time data between IT systems and OT operations, providing platforms for advancement of simulation solutions.

Contact us for more information