Latest news

OMRON awarded third EcoVadis Platinum Rating for outstanding sustainability performance

26. helmikuuta 2024 OMRON has achieved the prestigious Platinum rating from EcoVadis, placing it in the top 1% of all businesses assessed for sustainability performance. This marks the third time that OMRON has received this international recognition.

OMRON's ESG efforts rated highly by Dow Jones Sustainability World Index for seventh consecutive year

25. tammikuuta 2024 OMRON has been listed within the top 97% among peer sector companies on the globally recognized Dow Jones Sustainability World Index (DJSI World*1), an SRI (socially responsible investment*2) stock price index.

-

OMRON K7DD - The Power Quality Monitoring Device

Introducing the OMRON K7DD Power Quality Monitoring device—a game-changer in advanced motor condition monitoring! Swiftly identify failure modes and defective motor parts by translating motor current and voltage into actionable data. Now, conduct scheduled maintenance with real-time monitoring for motors that undergo frequent speed changes, addressing abnormalities that were once hard to detect. Experience enhanced efficiency with the simplified parameter configuration process, ensuring a quick grasp of K7DD installation. Elevate your motor equipment's performance with OMRON's cutting-edge technology!

02:05

OMRON releases K7DD-PQ Series of advanced motor condition monitoring devices

11. tammikuuta 2024 Preventing unexpected equipment failure by monitoring difficult-to-measure failure modes, including frequent speed changes and motors with rapidly changing loads

OMRON awarded gold rating for LGBTQ+ initiatives for the 6th consecutive year

04. joulukuuta 2023 OMRON is proud to announce that it has been awarded the Gold Standard Workplace rating under the PRIDE Index for the sixth consecutive year. The PRIDE Index, developed by ‘work with Pride’, evaluates companies and organizations for their initiatives related to sexual minorities, including LGBTQ+. This recognition reflects OMRON's ongoing commitment to promoting diversity and inclusivity within the workplace.

OMRON invests in SALTYSTER's embedded high-speed data integration technology

28. marraskuuta 2023 Achieving economic and social value through integrated production site information control

OMRON introduces new MD-series autonomous mobile robots for medium payload range

13. marraskuuta 2023 Enhanced efficiency in material transfer with medium-duty payloads and integrated control technology

Edzcom joins OMRON’s Innovation Network as Alliance Partner

24. lokakuuta 2023 Converging automation and connectivity through Private 5G Networks

OMRON Robotics and Safety Technologies enters strategic partnership with Lowpad for mobile robots

16. lokakuuta 2023 OMRON Robotics and Safety Technologies, Inc. and Lowpad BV are pleased to announce a strategic partnership to expand OMRON’s line of mobile robots with Lowpad’s low-profile product offering.

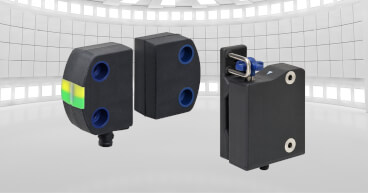

Winner of 2023 Good Design Award: New OMRON V460-H intelligent DPM reader with advanced Ethernet connectivity

13. lokakuuta 2023 OMRON, a global leader in industrial automation has launched the new V460-H Intelligent Direct-Part Mark (DPM) Industrial Reader. This rugged handheld reader delivers advanced decoding performance while offering Ethernet network connectivity to meet the needs of today's dynamic manufacturing and logistics sectors.

New OMRON TM S Series Collaborative Robots: Faster Joints and Expanded Safety Features

26. syyskuuta 2023 OMRON has announced the availability of the OMRON TM S Series collaborative robots, designed for diverse applications across multiple industries. These cobots introduce advanced hardware, more safety features and certifications, and next-generation configuration capabilities, making them easier to use than ever before.

OMRON expands automation portfolio with innovative Industrial Part Feeder (iPF)

29. elokuuta 2023 One-stop solution combining the feeding system, robots, vision and software cuts design and commissioning time by 70%

Introducing the OMRON V450-H DPM handheld scanner

11. elokuuta 2023 Setting new standards for durability and performance in industrial scanning of direct part marks

Increased precision: Robert Bosch GmbH chooses new OMRON inline 3D CT X-ray inspection system VT-X750

04. elokuuta 2022 Printed circuit boards (PCBs) are central component of numerous electrical devices, and the automotive industry is also increasingly dependent on PCBs that do not have any weak points.

OMRON Adds Selectable Autonomy and FLOW iQ to FLOW Core Fleet Management Software

11. heinäkuuta 2022 Driving flexible manufacturing with mobile robots in complex material transport applications

OMRON launches K7TM condition monitoring device for predictive maintenance of heaters

28. huhtikuuta 2022 OMRON's new K7TM condition monitor for heater equipment in automotive and FMCG industries contributes to the realization of a carbon-free society.

OMRON adds new food-grade models to its i4H SCARA lineup

20. huhtikuuta 2022 OMRON introduces the additions of new food-grade robots to the i4H product line for safe handling in the food and beverage and packaging industry.

New FLOW Core 2.1 fleet management software

14. helmikuuta 2022 Smart factory support through installation simulation and driving data analysis improves effectiveness

New V440-F Series ultra-compact, high-resolution, networked code reader

16. joulukuuta 2021 OMRON expands the MicroHAWK range with the V440-F, which is ideal for reading multiple codes in a wide area, as well as for applications over longer distances and with minuscule barcodes.

New RT1-Series Site Manager for Secure Remote Access

09. joulukuuta 2021 Security certified IIoT edge gateway enables remote troubleshooting and monitoring

Introducing the world’s most advanced 3D AOI system: Our new S10 Series -ultimate solution for manufacturers’ new challenge: “Unmanned inspection System”

01. syyskuuta 2021 The world of automation is in consistent movement, and it is no secret that today’s manufacturing environment is complex! Trusted for almost 90 years, we are a world leader in automation and, the global market leader in Automated Optical Inspection systems solutions during the past 35 years. We are proud of introducing our new S10 Series, the world’s 1st full colour system, offering a unique mix of general purpose and application specific solutions. S10 Series enable flexible manufacturing, respond to shortages in manpower and demands for higher quality production.

Introducing the D41 Series High-Coded Safety Door Switch

05. heinäkuuta 2021 Reducing the risk of interlock devices being deactivated, for a safe and worry-free production site.

Upgrade now from CP1E to CP2E Compact Controller with fully backward compatibility!

01. heinäkuuta 2021 Are you using CP1E Controller? Time to upgrade now, empower your Machines with CP2E Controller without minimal effort. It is fully backward compatible with your CP1E and offers more functions to be future proof.

NX-TC makes sealing PERFECT!

15. toukokuuta 2021 The temperature of sealing in-sync with machine motion

Book your Personalised Inspection Systems Division (ISD) Product Demonstration

10. toukokuuta 2021 Contact us to receive a practical on-line demonstration and to discuss the transformation of Manufacturing Quality Improvement

OMRON launches ROI calculator for mobile and collaborative robots

01. syyskuuta 2022 A new ROI calculator from OMRON has been launched to support the process of evaluating an investment in collaborative and mobile robots, including easy and affordable leasing opportunities that are ideal for small and medium enterprises (SMEs).

OMRON Acquires Science Based Targets Initiative Certification

19. heinäkuuta 2022 Based on the greenhouse gas (GHG) emissions reduction targets set in its long-term vision, Shaping the Future 2030 (SF2030), OMRON paves the way for achieving the goal of limiting global warming to 1.5 degrees Celsius advocated by the Paris Agreement.

Multiple vulnerabilities in Machine Automation Controller NJ/NX series

01. heinäkuuta 2022 Information on the vulnerabilities that exist in the NJ/NX series.

OMRON’s Flexible Manufacturing Roadshow travels across Europe

08. kesäkuuta 2022 Our Flexible Manufacturing Roadshow has embarked on a unique journey across Europe, featuring exclusive demonstrations of human-machine collaborative solutions not usually seen outside of a factory setting due to their size and scale.

OMRON announces “Shaping the Future 2030” vision

05. huhtikuuta 2022 Targets 930 billion yen net sales and 120 billion yen operating income in the 1st phase (FY 2024)

OMRON brings real manufacturing evolution to factory floors today at Hannover Messe 2022

04. huhtikuuta 2022 Automation beyond human abilities, advanced collaboration between people and machines and accelerating digital transformation at manufacturing sites will help manufacturers realize flexible, efficient, and sustainable production. Visit OMRON at Hannover Messe 2022 (30 May – 2 June) in hall 9, booth F24.

Discover career opportunities at OMRON

23. maaliskuuta 2022 OMRON has recently launched a global career site, offering positions ranging from student programs to full-time positions worldwide.

OMRON Awarded the Silver Class Distinction in the S&P Global Sustainability Awards 2022

16. maaliskuuta 2022 OMRON has been awarded the Silver Class distinction in the S&P Global Sustainability Awards, showcasing the sustainability performance of the world's largest companies.

OMRON Receives Top 100 Global Innovators 2022 Award

16. maaliskuuta 2022 OMRON has been selected as one of the Top 100 Global Innovators 2022 for the sixth consecutive year.

OMRON ilmoittaa hinnanmuutoksesta 2.5.2022 alkaen

03. maaliskuuta 2022 Siitä huolimatta, että näemme myönteisiä merkkejä Euroopassa liittyen COVID-19:ään ja yritysten elpymiseen, ovat maailmanlaajuiset toimitusketjut edelleen erittäin haasteellisia.

OMRON announces price updates implemented from 2nd May 2022

03. maaliskuuta 2022 Despite the positive signs we see in Europe regarding COVID-19 and business recovery, we recognise that global supply chains remain very challenged.

OMRON Appoints Fernando Colás as CEO of the Industrial Automation Business (IAB) in Europe

21. helmikuuta 2022 HOOFDDORP, The Netherlands — OMRON today announced that Fernando Colás, a highly experienced executive with the company for over 37 years, has been named as Chief Executive Officer (CEO) of its Industrial Automation Business (IAB) in EMEA. Colás follows Seigo Kinugawa, who will return to Japan to head the Global Business Process and IT Innovation HQ.eNews explained

Subscribe to Omron’s eNews today and you will receive the latest copy of our email newsletter, eNews.

Learn more