FHV7-AI

AI Detection Camera Smarter Vision. Lower Costs

- Self Learn: Automatic self-learning & optimization settings.

- Simplified Software: Seamlessly integrate multiple cameras for comprehensive inspection coverage.

- Rugged Design: IP-67 pre-assembled hardware.

- Flexible Configuration: 1.6MP Colour sensor, White LED lighting & Autofocus lens allow for simple installation.

- Robust Integration Capabilities: Easily integrate our FHV7-AI Detection camera with existing machinery and automation systems for seamless operation.

Specifications & ordering info

| Product | Focal length | Focus distance | Description | |

|---|---|---|---|---|

|

|

6 mm | 60-1000 mm | AI Detection Camera, focal length 6 mm, colour type, 1.6 Mpix resolution, white illuminator, motorized lens module, 24 VDC, IP67, pre-assembled |

|

|

|

9 mm | 60-1000 mm | AI Detection Camera, focal length 9 mm, colour type, 1.6 Mpix resolution, white illuminator, motorized lens module, 24 VDC, IP67, pre-assembled |

|

|

|

12 mm | 60-1000 mm | AI Detection Camera, focal length 12 mm, colour type, 1.6 Mpix resolution, white illuminator, motorized lens module, 24 VDC, IP67, pre-assembled |

|

|

|

16 mm | 110-2000 mm | AI Detection Camera, focal length 16 mm, colour type, 1.6 Mpix resolution, white illuminator, motorized lens module, 24 VDC, IP67, pre-assembled |

|

|

|

25 mm | 188-2000 mm | AI Detection Camera, focal length 25 mm, colour type, 1.6 Mpix resolution, white illuminator, motorized lens module, 24 VDC, IP67, pre-assembled |

|

Need assistance?

We’re here to help! Reach out, and our specialists will assist you in finding the best solution for your business.

Ota minuun yhteyttä FHV7-AI

Kiitos yhteydenotostasi. Otamme teihin yhteyttä mahdollisimman pian.

Meillä on teknisiä ongelmia. Emme ole pystyneet vastaanottamaan lomakettasi. Pahoittelemme ja pyydämme yrittämään uudelleen myöhemmin.

DownloadTarjous FHV7-AI

Tällä lomakkeella voit pyytää tarjouksen valitsemastasi tuotteesta. Täytäthän kaikki *-merkityt kentät. Henkilökohtaisia tietojasi käsitellään luottamuksellisesti.

Kiitos tarjouspyynnöstä. Toimitamme tarvittavat tiedot teille mahdollisimman pian.

Meillä on teknisiä ongelmia. Emme ole pystyneet vastaanottamaan lomakettasi. Pahoittelemme ja pyydämme yrittämään uudelleen myöhemmin.

DownloadFeatures

Intuitive on-screen Guidance

The Omron FHV7-AI Detection Camera provides a clear, user-friendly interface designed to make machine vision setup faster and more efficient. Operators can configure inspections with step-by-step guidance, while AI-assisted learning automatically adapts to variations in products and conditions. This combination reduces the need for manual adjustments, shortens deployment time, and ensures inspections are carried out with consistently high accuracy and reliability.

The left panel displays the step-by-step process to set up an inspection:

- Step-by-Step Adjustment Workflow

- Start Adjustment – Begin inspection setup with guided steps.

- Image Adjustment – Optimize brightness and focus for clear image capture.

- Register Master – Save a reference image as the standard for comparison.

- Learning – Teach the system typical variations for accurate recognition.

- AI Learning – Enhance detection performance using AI-driven training with minimal samples.

- Operation Check – Validate inspection accuracy before deployment.

- Finish Adjustment – Finalize and save inspection settings. Each step is highlighted sequentially, guiding users through the process

Smarter Quality Control with 3 pre-defined application types

- Item Presence – Detect whether all required components are in place.

- Product Type – Verify the correct product is used in assembly or packaging.

- Defect Detection – Identify scratches, dents, or damage before products ship.

Smarter AI Learning in Minutes

Flexible Autofocus for Any Product Size

All-in-One Design for Tough Environments

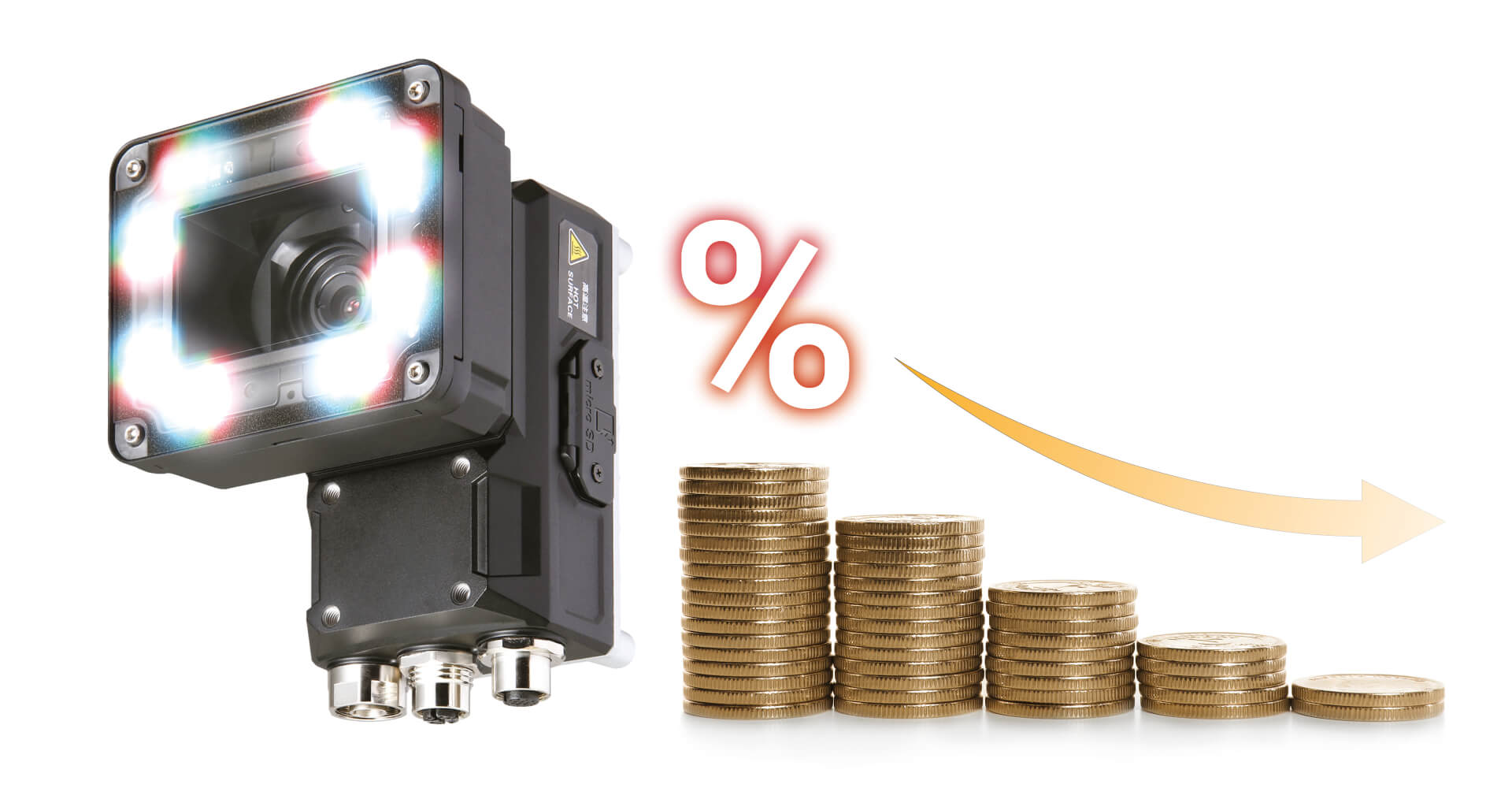

Low Cost of Ownership

- No Extra Hardware Needed – The integrated lighting, optics, and processing eliminate the need for external components and reduce setup expenses.

- Fast Setup & Easy Adjustment – Step-by-step guidance and AI learning minimize engineering time and speed up deployment.

- Maintenance-Free Operation – IP67 protection ensures reliable performance in harsh environments without the need for protective enclosures or frequent servicing.

- Scalable Across Applications – A single platform can handle multiple inspection tasks, lowering the need for different devices and spare parts.

- Long Lifecycle Support – Built with industrial-grade reliability, reducing downtime and replacement costs.

Applications

Date Code Presence Verification

❌ – The date code is missing, which could result in compliance issues and rejected products.

Product Orientation

❌ – The product is reversed, which could lead to misalignment, malfunction, or product failure.

Different Type Detection

❌ – An incorrect component type is identified, which could cause assembly errors, malfunctions, or defective products.

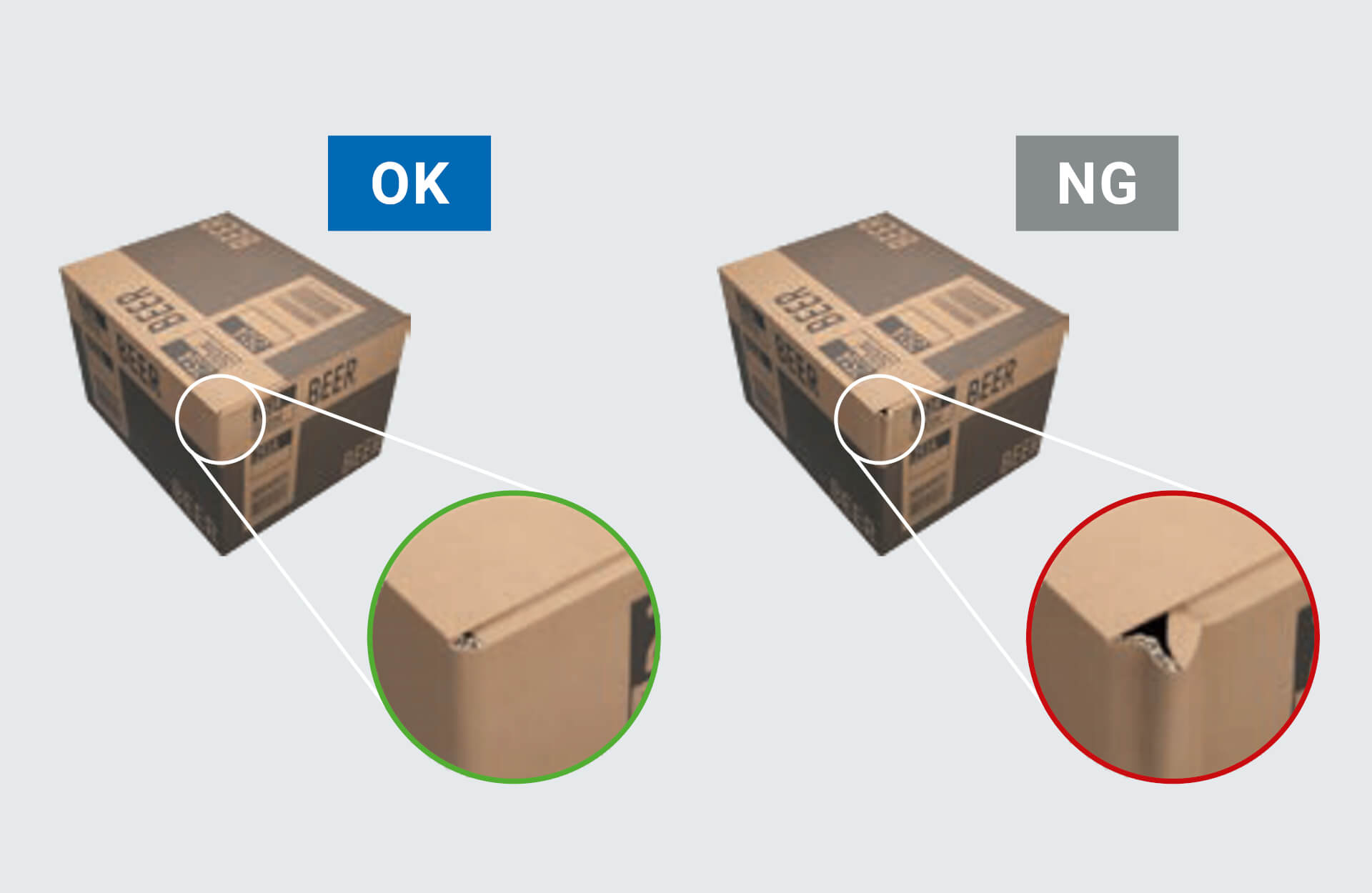

Simple Defect Inspection

❌ – A dent or tear is detected, which could compromise packaging integrity.

Videos

-

OMRON's FHV7-AI Detection Camera Overview

OMRON's FHV7-AI Detection Camera is designed to simplify and enhance automated judgment inspections. Combining advanced AI capabilities with an all-in-one lighting and lens setup, the FHV7-AI eliminates the need for specialized skills in building complex inspection systems. The camera automatically configures complex conditions and thresholds based on simple input from users, enabling the rapid creation of stable inspection processes. Read more:

01:41