-

Introducing OMRON HD-1500 Mobile Robot

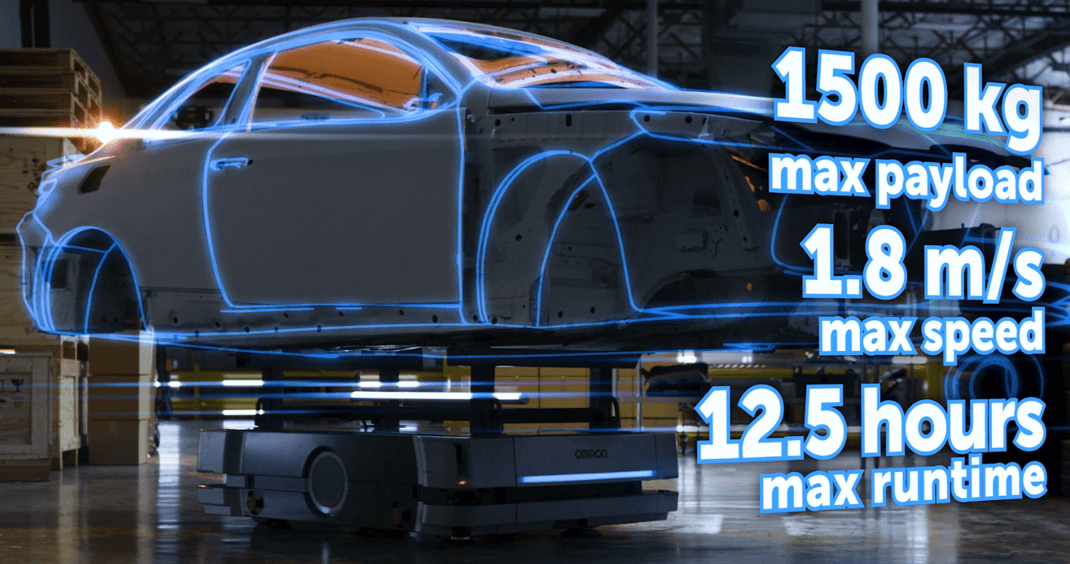

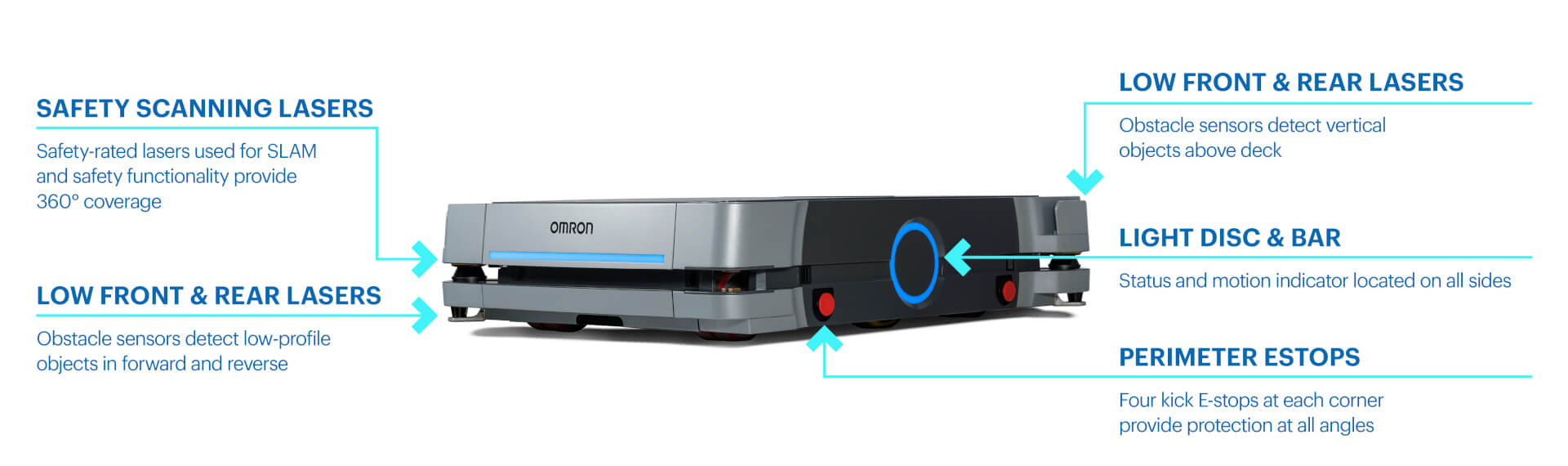

Introducing OMRON’s strongest mobile robot: the HD-1500. The HD-1500 is an advanced autonomous mobile robot specifically designed to transport heavy payloads up to 1500 kilograms. The HD-1500 also represents innovations in mobile robotics. Its new architecture features lasers that provide 360-degree safety coverage, as well as an onboard programmable logic controller, or PLC, to easily interface with custom attachments. Heavier payloads, built-in controller, improved sensors, route planning and object avoidance, the OMRON HD-1500 autonomous mobile robot offers the most advanced performance and safety. Learn more:

03:00

Introducing OMRON HD-1500 Mobile Robot

Introducing OMRON’s strongest mobile robot: the HD-1500. The HD-1500 is an advanced autonomous mobile robot specifically designed to transport heavy payloads up to 1500 kilograms. The HD-1500 also represents innovations in mobile robotics. Its new architecture features lasers that provide 360-degree safety coverage, as well as an onboard programmable logic controller, or PLC, to easily interface with custom attachments. Heavier payloads, built-in controller, improved sensors, route planning and object avoidance, the OMRON HD-1500 autonomous mobile robot offers the most advanced performance and safety. Learn more:

New HD-1500 mobile robot with 1500kg payload capacity

Industry-leading HD-1500 expands the possibilities for autonomous material transport

Features

Automate new jobs

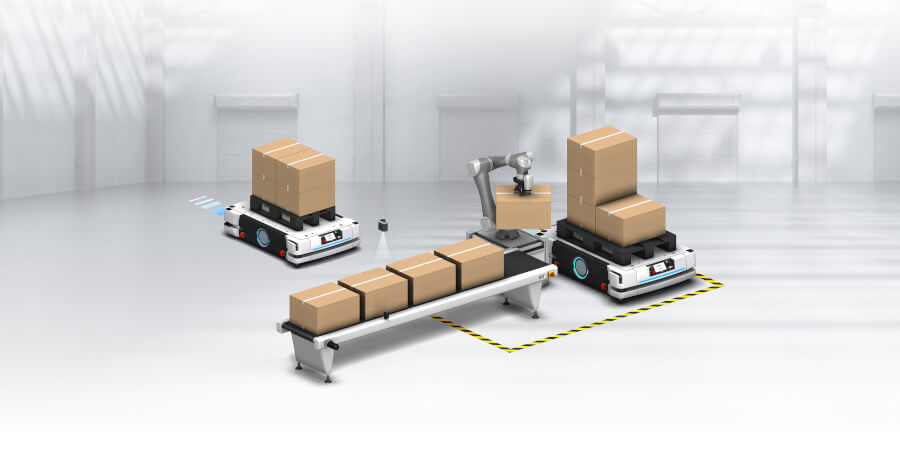

The higher payload capacity allows customers to automate new tasks that were not previously possible, such as the transport of pallet-size loads, engine blocks, and other heavy goods and equipment. The HD-1500 can also automate tasks that are traditionally completed with forklifts, reducing the risk of injury.

What to consider when selecting a mobile robot for heavy loads

Five questions to ask when selecting autonomous material transport technology for industrial applications.

Technology

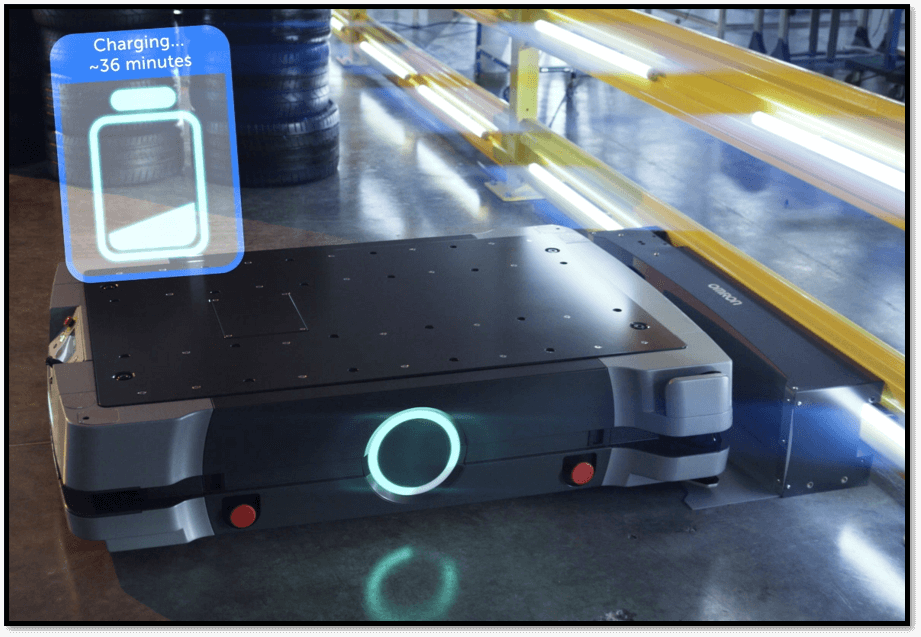

Rapid battery charging

- Charge from 5% to 80% in 35 minutes.

- 9 hours of run-time with a full payload.

- 12,5 hours of run-time unloaded.

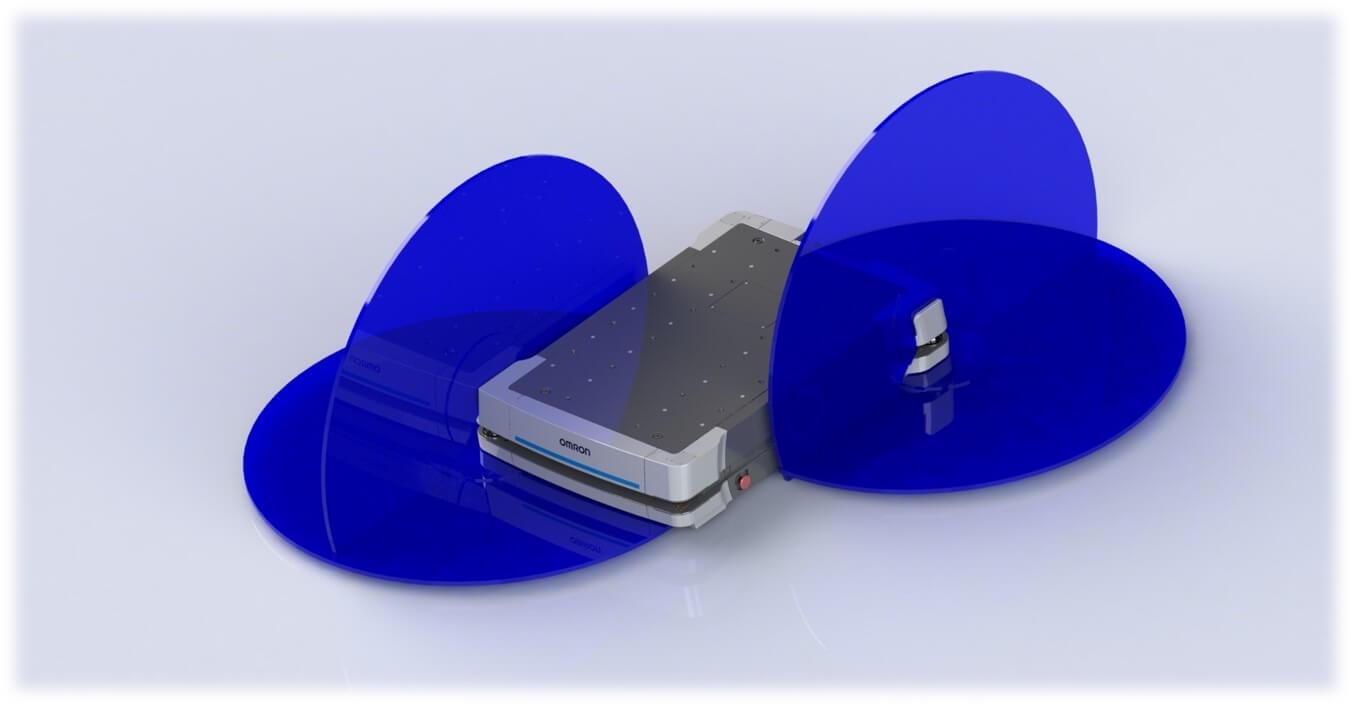

Safety

2 x LIDAR Laser, 2 x Lower Laser, 2 x Side Laser

AMR Technology and Software

OMRON's Autonomous Mobile Robots (AMRs) are equipped with dedicated AMR technology for navigation and alignment positioning. This technology allows the AMRs to move safely and efficiently within their designated workspaces, even in complex environments. The AMRs are also operated by software, which makes them easy to use and program.

- The dedicated AMR technology used by OMRON's AMRs includes a variety of sensors, such as laser scanners, which allow the robots to accurately map their environment and navigate safely.

- The software used to operate OMRON's AMRs is user-friendly and intuitive, making it easy to program the robots to perform specific tasks.

On-board user accessible Omron Machine Controller

- Dedicated IO through Omron’s Sysmac platform

- Control attachment and user peripherals with NX series machine controller

- Integrated Safety

Specifications & ordering info

| Product | Mobile robot type | Maximum load | Maximum speed | Kit type | Accessories included | Battery included | Description | |

|---|---|---|---|---|---|---|---|---|

|

|

OEM robot | 1500 kg | 1.8 m/s | Mobile robot + docking kit | Docking station | No | Mobile Robot, HD-1500, without Battery |

|

|

|

OEM robot | 1500 kg | 1.8 m/s | Mobile robot only | HAPS (dual) | No | Mobile Robot, HD-1500, Double HAPS, without Battery |

|

|

|

OEM robot | 1500 kg | 1.8 m/s | Mobile robot + starter kit | Docking station, Pendant, Top plate | No | Mobile Robot Starter Kit, HD-1500, Charger, Pendant, Top Plate, without Battery |

|

|

|

OEM robot | 1500 kg | 1.8 m/s | Mobile robot + starter kit | Docking station, HAPS (dual), Pendant, Top plate | No | Mobile Robot Starter Kit, HD-1500, Double HAPS, Charger, Pendant, Top Plate, without Battery |

|

Accessories

We’re Here to Help

Got a question? Our specialists are ready to assist you every step of the way.

Ota minuun yhteyttä HD-series

Kiitos yhteydenotostasi. Otamme teihin yhteyttä mahdollisimman pian.

Meillä on teknisiä ongelmia. Emme ole pystyneet vastaanottamaan lomakettasi. Pahoittelemme ja pyydämme yrittämään uudelleen myöhemmin.

DownloadTarjous HD-series

Tällä lomakkeella voit pyytää tarjouksen valitsemastasi tuotteesta. Täytäthän kaikki *-merkityt kentät. Henkilökohtaisia tietojasi käsitellään luottamuksellisesti.

Kiitos tarjouspyynnöstä. Toimitamme tarvittavat tiedot teille mahdollisimman pian.

Meillä on teknisiä ongelmia. Emme ole pystyneet vastaanottamaan lomakettasi. Pahoittelemme ja pyydämme yrittämään uudelleen myöhemmin.

DownloadVideos

-

OMRON's HD-1500 autonomous mobile robot for pallet-size loads

This is the HD-1500, OMRON's newest and strongest autonomous mobile robot. The HD-1500 can carry payloads of up to 1,500 kg, and can load and transport the heaviest of objects. The HD-1500 is ideal for applications that require moving pallet-size loads. Mobile robots in the production and warehouse environments help to reduce the workload of employees, take over routine tasks and comply with hygiene regulations, for example now during a pandemic. It’s designed to meet the industry’s latest requirements, and can interact with people to create a collaborative, safe working environment. In warehousing and manufacturing, the HD-1500 can make processes more efficient working safely side-by-side with humans, and reducing the risk of employee injury in dangerous situations. Take a look at it in action at our Proof of Concept area at our Automation Technology Centre for Autonomous Mobile Robots in Annecy, France. Read more:

01:11

OMRON's HD-1500 autonomous mobile robot for pallet-size loads

This is the HD-1500, OMRON's newest and strongest autonomous mobile robot. The HD-1500 can carry payloads of up to 1,500 kg, and can load and transport the heaviest of objects. The HD-1500 is ideal for applications that require moving pallet-size loads. Mobile robots in the production and warehouse environments help to reduce the workload of employees, take over routine tasks and comply with hygiene regulations, for example now during a pandemic. It’s designed to meet the industry’s latest requirements, and can interact with people to create a collaborative, safe working environment. In warehousing and manufacturing, the HD-1500 can make processes more efficient working safely side-by-side with humans, and reducing the risk of employee injury in dangerous situations. Take a look at it in action at our Proof of Concept area at our Automation Technology Centre for Autonomous Mobile Robots in Annecy, France. Read more:

-

OMRON Mobile I/O Box Tutorial Video

The OMRON Mobile I/O Box is an I/O device that can be used to summon an autonomous mobile robot (AMR) to a designated location by just pressing a button. #mobilerobots #omronindustrialautomation

08:56

OMRON Mobile I/O Box Tutorial Video

The OMRON Mobile I/O Box is an I/O device that can be used to summon an autonomous mobile robot (AMR) to a designated location by just pressing a button. #mobilerobots #omronindustrialautomation

-

OMRON FLOW Core 3.0 MobilePlanner

Our MobilePlanner allows you to easily and effectively utilize fleets of heterogeneous robot types alongside one another to optimize their automation solution. MobilePlanner expands our Fleet Management ecosystem as the best in the industry. #omronindustrialautomation #mobilerobots

00:53

OMRON FLOW Core 3.0 MobilePlanner

Our MobilePlanner allows you to easily and effectively utilize fleets of heterogeneous robot types alongside one another to optimize their automation solution. MobilePlanner expands our Fleet Management ecosystem as the best in the industry. #omronindustrialautomation #mobilerobots

-

OMRON HD-1500 Tutorial 1: Unboxing Preparation

Have a look at this video to see what steps are needed to get started with the HD-1500 autonomous mobile robot to support your material transport needs. With a payload capacity of 1500kg, the HD-1500 is OMRON's strongest mobile robot. We have prepared a series of videos to help you get started. In this video, you can see what tools are needed for unboxing, and what steps you should take to prepare the unboxing.

02:26

OMRON HD-1500 Tutorial 1: Unboxing Preparation

Have a look at this video to see what steps are needed to get started with the HD-1500 autonomous mobile robot to support your material transport needs. With a payload capacity of 1500kg, the HD-1500 is OMRON's strongest mobile robot. We have prepared a series of videos to help you get started. In this video, you can see what tools are needed for unboxing, and what steps you should take to prepare the unboxing.

-

OMRON HD-1500 Tutorial 2: Unboxing Charging Station Crate

Take a look at the steps needed to unbox the charging station crate.

01:30

OMRON HD-1500 Tutorial 2: Unboxing Charging Station Crate

Take a look at the steps needed to unbox the charging station crate.

-

OMRON HD-1500 Tutorial 3: Unboxing Battery Crate

Take a look at this video for the steps needed to unbox the battery crate.

02:16

OMRON HD-1500 Tutorial 3: Unboxing Battery Crate

Take a look at this video for the steps needed to unbox the battery crate.

-

OMRON HD-1500 Tutorial 4: Unboxing the HD-1500 autonomous mobile robot for heavy loads

In this video, we will show you two methods for unboxing the HD-1500, the lift method and ramp method. We will also show you how to get the HD-1500 on the network once it's unboxed.

10:42

OMRON HD-1500 Tutorial 4: Unboxing the HD-1500 autonomous mobile robot for heavy loads

In this video, we will show you two methods for unboxing the HD-1500, the lift method and ramp method. We will also show you how to get the HD-1500 on the network once it's unboxed.

-

OMRON HD-1500 Tutorial 5: Unboxing the Charging Target Crate

See this video for the steps needed to unbox the charging target crate for the HD-1500 autonomous mobile robot.

01:22

OMRON HD-1500 Tutorial 5: Unboxing the Charging Target Crate

See this video for the steps needed to unbox the charging target crate for the HD-1500 autonomous mobile robot.

-

OMRON HD-1500 Tutorial 6: Connecting to MobilePlanner

OMRON's mobile robot user interface is MobilePlanner. This enables you to configure the robot, create and edit maps, and make the robot do tasks and much more. In this video, you can see how you can connect the HD-1500 autonomous mobile robot for heavy loads to MobilePlanner.

02:50

OMRON HD-1500 Tutorial 6: Connecting to MobilePlanner

OMRON's mobile robot user interface is MobilePlanner. This enables you to configure the robot, create and edit maps, and make the robot do tasks and much more. In this video, you can see how you can connect the HD-1500 autonomous mobile robot for heavy loads to MobilePlanner.

-

OMRON HD-1500 Tutorial 7: Adding the HD-1500 to Mobile Robot Fleet

After you have completed the initial setup of the HD-1500 autonomous mobile robot for heavy loads, this video will show you how you can add your robot into a new or existing fleet of mobile robots.

06:21

OMRON HD-1500 Tutorial 7: Adding the HD-1500 to Mobile Robot Fleet

After you have completed the initial setup of the HD-1500 autonomous mobile robot for heavy loads, this video will show you how you can add your robot into a new or existing fleet of mobile robots.

-

OMRON HD-1500 Tutorial 8: Autonomous Mobile Robot Safety

This video highlights some of the safety features of the HD-1500 autonomous mobile robot for heavy loads, and demonstrates how to safely commission the mobile robot.

03:52

OMRON HD-1500 Tutorial 8: Autonomous Mobile Robot Safety

This video highlights some of the safety features of the HD-1500 autonomous mobile robot for heavy loads, and demonstrates how to safely commission the mobile robot.

-

OMRON HD-1500 Tutorial 9: Autonomous Mobile Robot Battery Replacement

This tutorial video demonstrates how you can remove and insert a new battery for the HD-1500 autonomous mobile robot for heavy loads.

03:03

OMRON HD-1500 Tutorial 9: Autonomous Mobile Robot Battery Replacement

This tutorial video demonstrates how you can remove and insert a new battery for the HD-1500 autonomous mobile robot for heavy loads.

-

OMRON FLOW Core 3.0 Cell Alignment Positioning System (CAPS)

CAPS technology utilizes any compatible laser to detect a customizable target in the environment and enables the AMR to drive to the required location with unrivalled precision. #omronindustrialautomation #mobilerobots

00:46

OMRON FLOW Core 3.0 Cell Alignment Positioning System (CAPS)

CAPS technology utilizes any compatible laser to detect a customizable target in the environment and enables the AMR to drive to the required location with unrivalled precision. #omronindustrialautomation #mobilerobots

-

OMRON FLOW Core 3.0 Dynamic Obstacle Tracking

Collaborative and intuitive robot motion with “pass-behind” decision making for a better decision-making and path planning. #omronindustrialautomation #mobilerobots

00:34

OMRON FLOW Core 3.0 Dynamic Obstacle Tracking

Collaborative and intuitive robot motion with “pass-behind” decision making for a better decision-making and path planning. #omronindustrialautomation #mobilerobots

-

OMRON FLOW Core 3.0 MobilePlanner Tablet

The MobilePlanner tablet edition is an easy-to-use interface designed to monitor and control your Mobile Robot fleet from a tablet. #omronindustrialautomation #mobilerobots

00:46

OMRON FLOW Core 3.0 MobilePlanner Tablet

The MobilePlanner tablet edition is an easy-to-use interface designed to monitor and control your Mobile Robot fleet from a tablet. #omronindustrialautomation #mobilerobots

-

OMRON FLOW Core 3.0 Selectable Autonomy

Enables users to tailor traffic flow with powerful path modes, ranging from autonomous guided vehicle (AGV)—but without the costly infrastructure—to limited detour windows, to the pure flexibility of a traditional AMR. #omronindustrialautomation #mobilerobots

01:09

OMRON FLOW Core 3.0 Selectable Autonomy

Enables users to tailor traffic flow with powerful path modes, ranging from autonomous guided vehicle (AGV)—but without the costly infrastructure—to limited detour windows, to the pure flexibility of a traditional AMR. #omronindustrialautomation #mobilerobotsDownloads

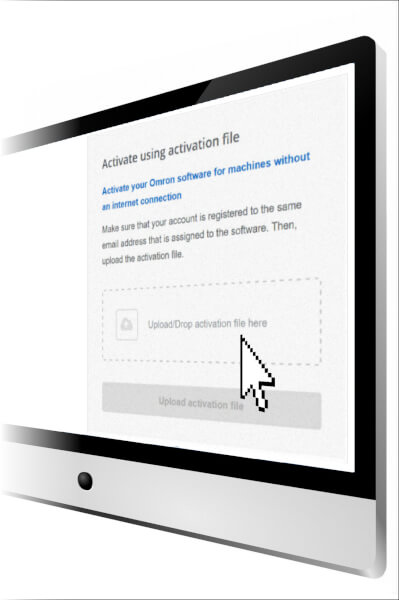

Activate your Mobile Robot Software

Easily apply online to request the activation of your Mobile Robot solution licenses. Use this form to request the activation of the Mobile Robot solution licenses for any of the different devices: LD-series, MD-series, HD-series, EM2100 and Virtual Fleet Manager. Start your activation process now.

Need assistance?

We’re here to help! Reach out, and our specialists will assist you in finding the best solution for your business.

Ota minuun yhteyttä HD-series

Kiitos yhteydenotostasi. Otamme teihin yhteyttä mahdollisimman pian.

Meillä on teknisiä ongelmia. Emme ole pystyneet vastaanottamaan lomakettasi. Pahoittelemme ja pyydämme yrittämään uudelleen myöhemmin.

DownloadTarjous HD-series

Tällä lomakkeella voit pyytää tarjouksen valitsemastasi tuotteesta. Täytäthän kaikki *-merkityt kentät. Henkilökohtaisia tietojasi käsitellään luottamuksellisesti.

Kiitos tarjouspyynnöstä. Toimitamme tarvittavat tiedot teille mahdollisimman pian.

Meillä on teknisiä ongelmia. Emme ole pystyneet vastaanottamaan lomakettasi. Pahoittelemme ja pyydämme yrittämään uudelleen myöhemmin.

Download

_reference_manual_en.jpg)

_leaflet_en.jpg)