Our Approach

- automate quality inspection tasks that require expert skills

- improve flexibility, productivity and adaptability

- reduce scrap and waste

- improve OEE and product quality

Our Solution

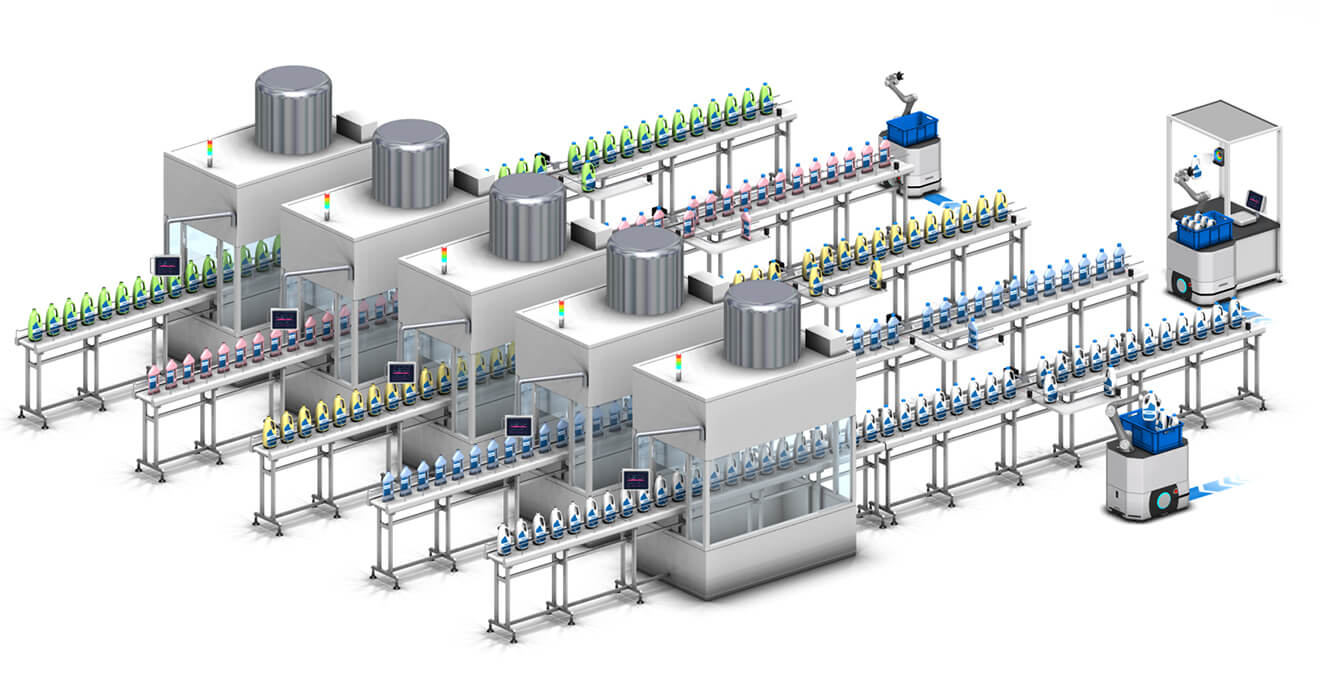

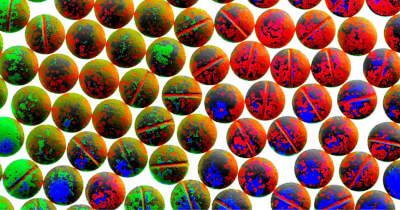

To overcome the hurdle of large visual variation between different products that are acceptable in quality inspection, OMRON has developed a solution based on artificial intelligence (AI) algorithms for defect detection that mimics the skills of experienced quality inspectors enabling:

- automating the detection of subtle defects and deviations with human-like sensitivity

- agile workflows in manufacturing

- continuous production solutions even in times of personnel shortages

- a solution that learns by means of images with defects instead of looking for specific defects

Benefits of adaptive inspection:

-

ensure flexible and consistent quality through smart automation

-

reduce waste

-

avoid human errors

Interesting to Read

Interested in the latest developments? Visit our news blogs for current updates!

How can adaptive AI inspection contribute to flexible manufacturing?

04. lokakuuta 2022 Consumers today demand customized products to meet their personal needs and tastes. Instead of producing items that are ‘made to shelve’ and ‘sent to stock’, manufacturers must personalize products that are ‘made for me’ and ‘sent to me’. This is revolutionizing production and forcing companies to rethink their processes. At the same time, ensuring zero complaints and zero defects is a must.The trained eye of an experienced vision inspector is quick to spot errors, but a routine task like this is tiring, and cannot be carried out at each step of the production, especially due to the current labor shortages in many industries. But could this task be automated also in high-mix low-volume production? Could a smart vision system or an ‘electronic eye’ replicate the discernment of the human eye, with the added benefit of repeatability and robustness? The latest AI-enabled adaptive inspection can overcome the challenges of automated quality inspection, with improved flexibility, productivity, and adaptability.