Factbird

SOLUTION PARTNER

Factbird stands at the forefront of Manufacturing Intelligence Solutions, dedicated to enhancing operational efficiency.

The company zeroes in on data analysis, offering concrete insights that enable enterprises to streamline processes, minimize downtime, and increase productivity. By harnessing the latest technologies, Factbird provides immediate, actionable intelligence to help businesses thrive.

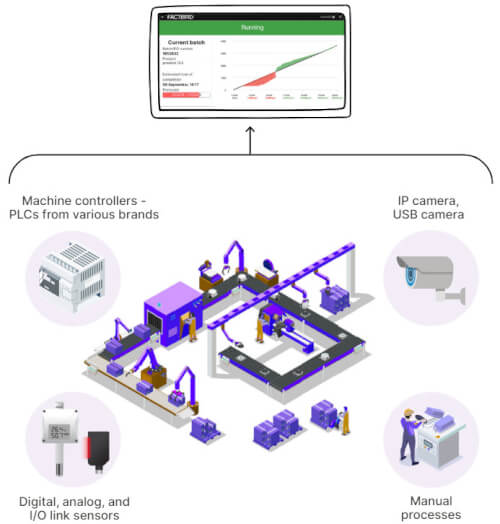

Factbird's solutions include automatic data collection devices, real-time OEE monitoring, video monitoring, process optimization, utility and resource monitoring, and proactive equipment maintenance capabilities.

Factbird gives you instant access to real-time production data from OMRON controllers (PLCs) for data-driven operational excellence. Factbirds customers will be able to make better decisions that increase the profitability and efficiency of operations by having total insight into production performance.

The Factbird manufacturing intelligence solution integrates diverse data from sensors, PLCs, cameras, and manual inputs like production counts and energy usage. This provides instant access to real-time manufacturing data, offering full visibility into production performance and supporting data-driven decisions to boost profitability and efficiency.