Automation blog

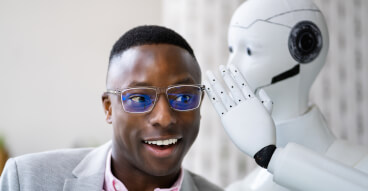

Collaborative capabilities

31. toukokuuta 2023 Omron Automation robotics can be used in collaborative applications, where they work alongside human operators to pick up and place objects. The robots are designed to be safe to work around, with sensors and other safety features that prevent collisions and other accidents. This allows manufacturers to use collaborative robotics in a wide range of applications, improving productivity and efficiency while maintaining a safe work environment. With collaborative capabilities, manufacturers can take advantage of the benefits of automation while still maintaining a human touch in their production processes.

Buying or Leasing? How to finance your new cobot

26. huhtikuuta 2023 Food for thought for SMEs when funding automation projectsSkills shortages, digitization, sustainability, and energy-saving plans are accelerating automation projects in many companies. Once manual processes that lend themselves to automation have been identified, the next question that usually follows is: And what does it all cost?It can make sense to consider options such as leasing or robot-as-a-service. One example of tools that give small and medium-sized enterprises (SMEs) in particular a better overview the financial aspects of automation is the ROI calculator from OMRON. Anyone currently considering the purchase of a cobot or AMR can use this tool to reveal the return on investment.

Why automated inspection systems are critical for electric vehicle manufacturing

23. maaliskuuta 2023 Safety trumps all other concerns in the automotive industry, and electric vehicle manufacturing is no exception. However, safety can also introduce complexity, and the complexity of today’s vehicles – particularly EVs – is such that manufacturers are no longer able to rely on traditional sample or audit-based inspection methods.

Can Artificial Intelligence (AI) in robot systems manage the functional safety parts?

20. maaliskuuta 2023 Authors: Josep Plassa, Safety Product Marketing Manager at OMRON Europe and Atsushi Oshiro, Manager at the OMRON Development CenterRobots and AI systems have become an integral part of industrial manufacturing sites. To ensure the safety of workers while using robots, a detailed risk assessment is necessary. This assessment is carried out from the perspective of Functional Safety, which examines the five main elements employed by robots to determine autonomous control actions: Environment recognition, Action planning, Trajectory generation, Motion control, and Measurement.

Artificial Intelligence: don’t call me stupid

08. helmikuuta 2023 Ten years ago I was quite proud of how smart the machines in our own factory were. Now, with my today’s definition of smart, I realise they were actually quite stupid.Why? Because although they were doing what they were designed to do, the minute they encountered anything unexpected or out of the ordinary they were stumped. They resorted to asking the operator ‘what is wrong with me?’.Troubleshooting and getting machines back up and running called for smart people. Highly skilled operators. Experienced software and hardware engineers. The problem is that in the last ten years, these people have become increasingly unavailable. There quite simply isn’t enough new talent entering the industry to offset the number of workers reaching retirement age. When they leave the business, retirees take with them their hard-earned on-the-job knowledge that is a culmination of years of experience. With each departing worker, businesses are faced with the prospect of a less productive and less skilled workforce.

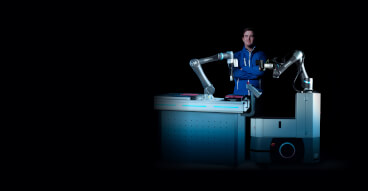

How to speed up cobot integration

08. helmikuuta 2023 Good planning and strong partners help SMEs overcome hurdles in automation.Collaborative robots, also known as cobots, are enjoying great popularity because they make it possible to automate time-consuming and resource-intensive tasks. The global market for collaborative robots is currently estimated at around $1.2 billion. The sales volume of cobots reached a total of 32,300 units in 2021. Especially in times when it is becoming increasingly difficult for companies to find and retain suitable employees, such technologies are worth their weight in gold in many places. Speaking of gold, some may ask: Cobots must be extremely expensive, right? When does such an investment pay off?Automation expert OMRON would like to alleviate such worries, especially for small and medium-sized companies: Smart and integrated robotics solutions as well as cobots and mobile robots are feasible and affordable. For those who want to estimate the return on investment, OMRON’s ROI calculator provides a quick and easy overview.Cobots and autonomous mobile robots (AMR) are suitable for both SMEs and large-scale businesses. They perform tasks such as transport, palletizing, loading and unloading of machines, assembly, painting, or welding. They can be quickly and flexibly retooled and also programmed by non-experts. Material replenishment can be streamlined with AMRs, and machine and process loading with cobots. However, to successfully carry out such projects and accelerate robot integration, know-how and partners who are familiar with the subject matter are needed. And above all, employees must be informed and involved from the start of the project to be part of the change together.Here are some tips companies should keep in mind when integrating cobots:

Top 5 automation predictions for 2023 from OMRON Europe

01. helmikuuta 2023 While a new year is upon us, with all its opportunities, I'd like to highlight some of the top trends that will impact and shape industrial automation in 2023 and beyond. The manufacturing industries will continue to face many challenges, and riding them out will involve building resilience and flexibility into business models. At the same time, companies must embrace emerging technologies - sensing, robotics, 5G and artificial intelligence - to help them solve the problems they face due to societal challenges.

The path to net zero: talking tactics

01. helmikuuta 2023 The key to unlocking a net zero future in manufacturing is transforming the value chain through automation.In June 2022, New Scientist reported that a third of the world’s largest companies had net zero targets - significantly more than the same time last year.Whilst it is positive news that momentum is accelerating, the article went on to say that the details of how companies were planning to reach net zero were patchy.Which is not surprising really. Creating and implementing a net zero strategy is a huge undertaking for any business, especially with 80% of GHG emissions falling into Scope 3 - that is emissions that occur upstream or downstream in the value chain. This is a particular challenge for FMCG companies, whose supply chains and onward logistics are long and complex.Most of these businesses know what they need to do: decarbonise and circularise the value chain. And they have a strategy for doing this, which will generally cover: optimising the use of resources and energy, replacing high emission products and processes and eliminating waste.But translating intention into action is where the main challenge lies. This is where automation has a crucial role to play.Data collection and analysis is the key to successful net zero transition. Without it, how do companies know what their starting point is, where they need to improve, whether they have improved and by how much? Robust data is the foundation for turning a commitment into change, and for credibly and confidently communicating with stakeholders and delivering on climate ambitions.

Powering through the energy and fuel crisis with automation

07. joulukuuta 2022 To counter rising prices and meet environmental targets, industrial enterprises should explore how automation technologies from a single source might help contribute to their sustainability strategy.High energy and fuel prices are putting a strain on both households and industry. Not only is the situation negatively impacting financial plans and wallets, but the excessive prices are forcing some companies to cease production. According to Make UK 42% of manufacturers surveyed said that their electricity bills have increased by 100% in the past 12 months and 32% said that gas prices have increased by over 100% in the past year. A worrying 12% of manufacturers have already made job cuts as a direct result of increased energy bills.The war in Ukraine, Covid-19 pandemic, and gas pricing are only a few of the causes of the crisis, which impacts all sectors and has an impact on everything from power prices to supply chains. What should manufacturing companies consider now? Comprehensive automation strategies are essential for greater flexibility and energy efficiency. This includes innovative robotics paired with sensor and vision technology as well as artificial intelligence – AI at the Edge. In addition, real-time data from production plants can assist with detecting anomalies and improving overall equipment effectiveness (OEE).

Riders of the storm: navigating economic uncertainty by turning social challenges into tech opportunities

06. joulukuuta 2022 One of the questions I am often asked is what our strategy is, as an industrial automation business, for maintaining stable growth in a volatile and increasingly unpredictable global economy. My answer, as you might imagine, is not one sentence, although it is rooted in one concept: SINIC. SINIC stands for ‘Seed-Innovation to Need-Impetus Cyclic Evolution’ and is a theory that was developed by OMRON's founder, Dr. Kazuma Tateisi, in 1970. According to this philosophy, science, technology and society share a cyclical relationship, mutually impacting and influencing each other. Scientific breakthroughs help society to advance and social needs spur on technological development. OMRON Europe has always followed this philosophy, and has spent the last decade laying the foundations for creating value-adding solutions to present day social and economic challenges.

Four Automation Tips for SMEs

25. marraskuuta 2022 Corporate leaders around the world are currently facing one challenge after another: In addition to the exploding costs caused by the energy crisis, there are supply chain problems, a shortage of skilled workers, sustainability requirements, and advancing digitization issues. In particular, small and medium-sized enterprises (SME) need to quickly find ways to address these hurdles. Automation provides a remedy – this includes robotics such as cobots and AMR (autonomous mobile robots), as well as sensors, vision, and AI technology. While companies are well aware of the benefits of such technologies, studies also show that many remain skeptical of their actual use.Especially companies without application experience fear that the use of robots could be accompanied by high costs. So if you are currently wondering whether the purchase of a collaborative or mobile robot is worthwhile for your own business, OMRON's new ROI calculator will help. It provides a quick overview of the return on investment and shows when a robotics investment will cover its costs.

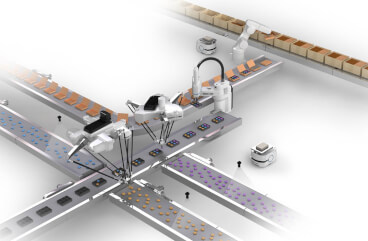

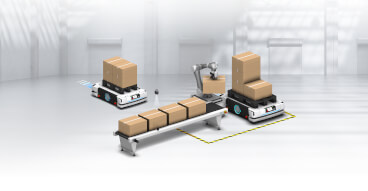

Where is the future heading, intralogistics? Tips for more efficiency

15. marraskuuta 2022 Sometimes we focus so much on the big picture that we forget the smaller and yet so important processes that characterize smart production. One example is intralogistics, i.e. the flows of materials and goods that take place on a company's premises or in a production hall. A recent study found that more than 80 percent of the companies surveyed consider the increased use of AI and automation in intralogistics to be necessary to meet challenges such as the shortage of skilled workers or growth plans.Automotive companies that want to meet market and customer requirements, increase efficiency and become more sustainable must come up with new ideas. Energy costs, the gas crisis, and rising inflation make this task even more difficult. Smart factory concepts that combine innovative automation, digitalization, and smart intralogistics approaches can provide valuable support. Some speak of Industry 4.0 in this context, others of the “factory of the future”, still others prefer Industrial Internet of Things (IIoT). But no matter which term you favor: The most important thing is to become active now and to rely on reliable partners. Intralogistics is a good starting point for quickly initiating change. Because action is urgently needed: many companies are currently severely limited due to the shortage of skilled workers. Modern technologies such as mobile robots can provide a remedy.

Automation for zero touch: Improving safety, quality and efficiency in F&B

15. maaliskuuta 2021 Recent innovations in automation, robotics, image processing and artificial intelligence (AI) can help companies to migrate towards zero touch processes.

Affordable automation: Leasing cobots and mobile robots for flexibility on the factory floor

04. maaliskuuta 2021 In line with the move to Industry 4.0, an increasing number of manufacturers are turning to automation as a way of streamlining processes and boosting productivity. A key aspect of this is the use of robots, often working alongside people in the factory. However, many companies might be reluctant to invest in additional automation, particularly following the economic difficulties presented by COVID-19. For manufacturers looking for an affordable solution, cost structures with leasing options are being implemented as an option to allow adaptability on the factory floor.

Four top tips for automation projects in the food and beverage industry

22. helmikuuta 2021 A challenge accelerated by the Coronavirus pandemic has seen producers having to juggle between longer term range proliferation centred on consumer demands, and range (SKU’s) reduction caused by retailers and consumers rapidly changing buying habits. Companies that break new ground by using innovative technologies not only gain agility but also reduce scrap, contamination risk, waste and losses.

Innovative cobot application improves safety at Leica Geosystems

11. helmikuuta 2021 Collaborative robot automates tray handling and improves safety and ergonomics in a hazardous working area.

Developing smart and flexible production: Norwegian university sets up new manufacturing lab packed with robots

10. helmikuuta 2021 The Norwegian University of Science and Technology (NTNU) has developed a new educational laboratory in Ålesund to facilitate learning and extend the implementation of automation and robotics amongst manufacturers in the region. The lab is packed with a wide range of OMRON solutions – both hardware and software.

Powering the European automotive industry

29. tammikuuta 2021 The European automotive industry is facing strong competition from Asia, as well as the economic challenges of the pandemic. It needs to develop innovative, future-proof strategies and technologies that will boost both efficiency and sustainability. Tony Seba from Stanford University believes that by 2025, no more new vehicles with (pure) combustion engines will be sold and there will be a move towards battery or hydrogen-powered fuel cells. Meanwhile, the industry faces falling sales, increasingly strict emissions regulations, new technologies, digitisation and changing consumer needs. Companies must respond by converting their production lines; becoming more agile; and introducing innovations that provide a competitive edge.

ControlTec helps Polish hospital tackle the pandemic with a UVC mobile robot

26. tammikuuta 2021 Using an OMRON LD mobile robot, ControlTec was one of the first companies in the world to develop a sterilisation robot equipped with a UVC irradiator.

Fast and safe transport on the factory floor

18. tammikuuta 2021 Improved efficiency and seamless material supply: in Austria, Philips is automating material transport by using AMRs from OMRON.

Improved flexibility, agility and traceability with mobile robots for Normagrup

06. tammikuuta 2021 Normagrup, which specialises in technologically advanced lighting, needed to automate the transport of materials between three production areas, the assembly area and an automated warehouse. This involved moving through narrow spaces shared with factory personnel.

Mobile robot streamlines food deliveries

30. marraskuuta 2020 A whistling autonomous mobile robot has been seen recently moving around the corridors of shopping centre in Helsinki, Finland. Operated by OMRON’s solution partner Dimalog, the robot was taking part in a month-long ‘Home On-Demand’ automated courier service trial.

3 Ways COVID-19 is Impacting Logistics Operations in the UK (and what to do about it)

04. marraskuuta 2020 By Stuart Coulton, Regional Manager, OMRON UK North

What to consider when selecting a mobile robot for heavy loads

11. syyskuuta 2020 Five questions to ask when selecting autonomous material transport technology for industrial applications.

High-speed robot tests the reliability of black boxes

14. toukokuuta 2020 A non-destructive alternative to crash tests

Integrated data control, motion control and machine vision for next-generation automotive production line

24. huhtikuuta 2020 The Mexican regional headquarters of a leading manufacturer of premium air brake actuators for global on-highway and specialty markets required a new automated production assembly line. One of the company’s key performance indicators is to deliver a fully assembled product every 30 seconds, and it is with this end goal at the forefront that the team started the process of automating the production line.

IoT security for manufacturers

11. joulukuuta 2019 The Internet of Things (IoT) is a recent concept, involving the connection of devices that incorporate electronics, software or sensors, with the aim of collecting and exchanging data.

Smart machines: laying the golden egg?

16. lokakuuta 2019 Greater manufacturing efficiency: it’s the golden egg we’re all looking for. But it’s getting increasingly hard to find. The solution could be smarter automation, which involves lots and lots of data (‘big data’) and data collection and data-driven modelling. The smart machine then uses the models to automatically adjust its own behaviour (i.e. machine learning).

A practical illustration of IoT and Industry 4.0

01. lokakuuta 2019 The Internet of Things (IoT) is a relatively new phenomenon. Prof Dr Thomas Pospiech, a teacher of Production and Process Management at Heilbronn University of Applied Sciences, was interviewed recently about the ‘IoT box’ he’s developed to give his students a practical illustration of this fairly abstract concept.

What is the effect of Brexit on automation in the UK?

26. syyskuuta 2019 Currently, workers from the EU have the right to travel and work freely across European borders. However, key statistics of net migration from the Office of National Statistics in the UK, show that net migration to the UK has been significantly reduced since 2016. With the announcement of Brexit, and the ensuing uncertainty around it, UK factories are perhaps no longer a viable destination for European workers.

How smart is your packaging line?

17. syyskuuta 2019 Industry 4.0 is changing the way in which manufactured goods are produced, through the use of automation and data exchange. By incorporating it into your packaging line, you can start to enjoy a range of benefits, from better data management to improved efficiency. Moving to a modern, flexible and smart line will bring the most benefits, but replacing a complete production line might not be a viable option if you’re operating with tight margins. However, even small changes to your existing facilities can significantly boost your efficiency.

Perfect Packaging, ordinary packaging executed extraordinary well

08. heinäkuuta 2019 Packaging processes rarely harbour extremely surprising variables. From manufacturers to system integrators, machine builders and industrial automation providers, we all know the essentials that make packaging production a definite success. However, the everyday reality on the factory floor is that small imperfections in the process result in major output disturbances. That is why Omron introduces its Perfect Packaging concept featuring smart innovations that ensure that ordinary F&B-packaging is executed extraordinary well. We help make your bottom-line top!

Go with the Adaptive and Dynamic production flow!

06. toukokuuta 2019 Flexible and fast responses to changes in market dynamics improve performance. Made-for-me production flows are the future of manufacturing coherent with Industry 4.0. A reality that Omron already provides today through its cutting edge innovative-Automation approach. Turning factory floor data into highly valuable information, we realize intelligent automation solutions for manufacturers around the globe.

Smart sensing for multiple materials!

06. toukokuuta 2019 You know the routine. Switching from one product to another on your production line means a costly full stop, making all kinds of changes, starting up again, discarding the materials and packaging already fed into the line together with start-up rejects, and only then can production resume. Well, have we got good news for you: smart sensing for multiple materials!

Rock solid results with flexible production & robotics!

06. toukokuuta 2019 Today's market requires an increasingly agile production environment. Traditional industrial automation and robots are often too inflexible to successfully accomplish mass customization. Omron is enabling smart Industry 4.0 scenarios with a rare combination of intelligent automation solutions and robotics. Perfecting seamless human-robot collaboration and making more and more use of AI-driven possibilities, we assist manufacturers in realizing rock solid results with flexible production and robotics.

Direct link IT & OT puts factories on cloud nine

25. helmikuuta 2019 Just imagine getting rid of cumbersome middleware or PC data concentrators at your production locations and being able to enjoy the benefits of direct database connectivity. Where Information Technology (IT) & Operational Technology (OT) come together something beautiful happens. We have created a production environment in which databases and machine controllers are best friends and keep in touch continuously.

Don't let vibrations catch you off balance!

25. helmikuuta 2019 Machine operators are aware that sudden increases in vibrations or noise variations can herald a serious shake-up on their production lines. Unfortunately, it is hard for humans to quickly notice the indicators of, for instance, out-of-balance mechanics. The human touch is no match for dedicated sensors combined with high-speed Analogue Input Units that can reliably, precisely, and easily acquire synchronized data.

Expect the unexpected: Prepare, Prevent & Predict

25. helmikuuta 2019 Sudden stops on a production line can cost a fortune. Avoiding unexpected stops and reducing scheduled downtime are key components to boost OEE. It sounds simple, but requires interpretation of the right, often complex, data. Artificial intelligence can optionally be deployed to interpret the collected relevant device and machine data real-time. Our solutions assist you to actively steer your operations to optimize the schedule for maintenance activities, and minimize maintenance and support costs.